1.0 General Information

Read this manual before beginning the installation so that you can

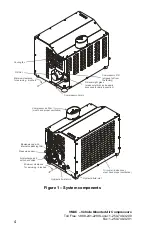

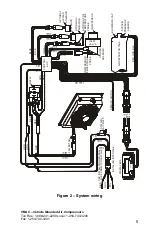

understand the hydraulic, electric (Figure 2) and ventilation

requirements. This will ensure a successful installation and effective

operation of the PREDATAIR (Figure 1).

1.1 Specifications and Components

This is a flooded-lobe, rotary screw compressor (filled with VMAC

certified and approved synthetic oil) driven by a hydraulic motor.

Compression occurs when inlet air (at normal atmospheric pressure)

enters a chamber where it is trapped between the rotating rotor

lobes. A lubricated pitch line provides sealing. As the lobes mesh,

they reduce the volume of the air, compressing it to the desired

pressure.

The system has a two-stage air/oil separator. The first separation

stage consists of baffles, which perform mechanical separation. The

second stage uses a special separation element, which delivers dry

air to the outlet.

Pressure regulation is achieved with a mechanical inlet control valve

and an adjustable pressure regulator.

The compressor is protected by a paper-type replaceable air filter

and a spin-on type oil filter. Oil is removed from the delivered service

air by a coalescing separator element.

Safety features include:

•

2,800 psi hydraulic pressure relief valve

•

200 PSI relief valve in oil/air tank

•

blow-down valve to discharge system pressure on shutdown

•

temperature safety sensor in compressor and hydraulic oil

Do not disable or bypass the over-temperature

shutdown circuit. Failure of the shutdown system could

result in equipment damage, injury or death.

!

A liquid-to-air cooler maintains operating temperatures in an optimal

performance range which increases system durability and reduces

the temperature of the compressed air.

The system pressure is factory-set at 150 psi. This can be adjusted

using the display box. To reduce the pressure, use a Filter Regulator

Lubricator (FRL).

VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

3