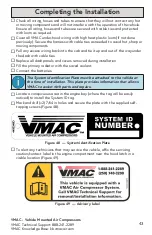

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: kb.vmacair.com

50

☐

Loosen the adjustment locknut (Figure 52).

☐

Adjust the priority valve to the desired flow rate via the adjustment spigot

(counterclockwise to increase flow, clockwise to decrease flow) (Figure 52).

☐

Once the adjustment has been completed, tighten the locknut.

While the PTO selector switch is set to “VARIABLE RPM”, vehicle

engine speed will vary dependent upon air demand.

☐

Ensure the hydraulic flow remains steady at any vehicle engine speed.

☐

Remove the flowmeter.

Final Testing

Ensure the following has been completed:

☐

Operate the system with an air tool (or the VMAC Air Test Tool with the

appropriate orifice installed) for at least 1/2 hour (1 hour preferred).

☐

Road test the vehicle for approximately 14 miles (20 km).

☐

Observe the compressor operation to ensure that the belt alignment is good

and nothing is rubbing or contacting hot components.

☐

Check all components, connections and fasteners once the engine is turned off

and the system has cooled.

☐

Check the coolant level after the engine has been operated.

☐

Check the compressor oil level after the engine has been shut down and the oil

level has had time to stabilize.

Set the PTO mode selector switch on the PTO indicator panel to “VARIABLE RPM”

and open the ball valve on the air test tool*.

☐

*Vehicle engine speed should increase to meet the demand for air.

Ensure the vehicle’s maximum engine speed does not exceed the

maximum rpm listed on page 52 (the maximum engine speed is

hydraulic pump model specific).