18

KLYS

EN

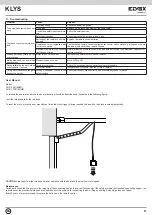

7. Control unit description (fig. 26):

Key:

1. Mains connection terminal

2. Removable terminal for connection of control inputs and safety devices

3. Quick-release motor and encoder connecting clamp

4. Quick-release emergency battery kit connecting clamp

5. Trimmer for adjusting the obstacle sensitivity

6. Configuration Dip-switch

7. Step-step control button (P/P)

8. Travel programming button (P1)

9. Remote control programming button (P2)

10. Fuse F2 8 AT 5 x 20 mm for protection of the motor power line and accessories

11. Fuse F1 1.6 AT 5 x 20 mm for protection of the switching power unit

12. Microprocessor

13. Power signalling LED

14. White courtesy LED light

8. Connection to the mains electricity (fig. 27)

Terminal no.

Terminal markings

Description

N

N

Neutral connection

Earth connection

L

F

Phase connection

That the motorisation is fitted with a pre-wired cable with a German standard plug, to connect an electrical cable directly to the control unit first remove the

existing wiring. Fig. 25 highlights the pilot holes to break and pass the wires through.

9. Accessories connection (fig. 28):

Terminal no.

Description

51-0

Input for activating step-step button (NO contact)

51 - NO contact

0 - common

62-0

Photocell input (NC contact)

62 - NC contact

0 - common

Note:

jumper if not used

61-0

Input for stopping button (NO contact)

61 - NC contact

0 - common

Note:

jumper if not used

0-1

Power supply output for accessories (24 Vdc, max 500 mA)

0 - negative

1 - positive

1-10

Flashing light power output, compatible only with LED flashing lights max 7 W

1 - positive

10 - negative

0-

Antenna connection

0 - earth

- signal

Fig. 25 highlights the pilot holes to break and pass the wires through.

Safety device connections

To connect

1

or

2

pairs of photocells in

closing

see fig 29

a

and fig.

29b

Installation of adapter boom:

- cut the curved drive plate (fig. 22a) so that it is only straight, Ø8 mm to enlarge the second hole of the perforated plate of the adapter arm, use this plate

as a template and drill 2 holes Ø8 mm part of the plate connected to the carriage previously cut (Fig. 22b)

- Install the arc exactly in the middle of the up-and-over door. Align the upper plate with the upper edge of the door. If the door frame cannot be used to

anchor the lower plate of the arc, create a special support in steel sheet (S) between two beams (fig. 23b)

Important:

make sure that the arc is perfectly aligned horizontally and vertically with the door closed. The misalignment of the arc plates to the door (the 4

sides of the plate not perfectly parallel to the 4 sides of the door) will cause the incorrect movement of the up-and-over door.

- fix the adapter boom to the drive plate in the holes made previously, using the M8 bolts supplied (fig. 23a).

- make sure that with the door closed the part of the adapter boom that slide on the arch is between 20 and 30 mm from the arc itself (fig. 23b).

Where necessary, cut the perforated part of the boom to be connected to the drive plate in the lower part and use the holes present to obtain the correct

measurement.

- release the operator (fig. 12) and check that the door moves correctly. Particularly check that there are at least 20 mm of available boom travel with the

door completely open.

Note:

the automation of an up-and-over door with counterweights with drive motorisation and adapter boom, causes greater stress on the track than the motor

drive of a sectional door. The track can be stiffened using additional brackets for fixing the track at a distance from the ceiling.

- To operate the external release with the door handle, run the cable sheath along the path indicated in fig. 24.

Summary of Contents for ELVOX KLYS ENM1

Page 3: ...3 KLYS 110mm 10mm max 38cm 60cm 7 5 6 8 9 10 a b a b Motor I EN...

Page 4: ...4 KLYS 45 11 12 14 13 15 16 I EN...

Page 6: ...6 KLYS 100 mm max 10 20 mm 8 m S 20 30 mm 8 mm 21 22 a b 23 a b I EN...

Page 7: ...7 KLYS 24 25 N L 1 11 2 3 4 13 5 12 8 9 6 10 7 14 51 62 61 0 1 10 5 26 27 115 230 V ac I EN...

Page 23: ...23 KLYS...