19

5354 788 - 03

Vitorond 200, VD2A Series Installation

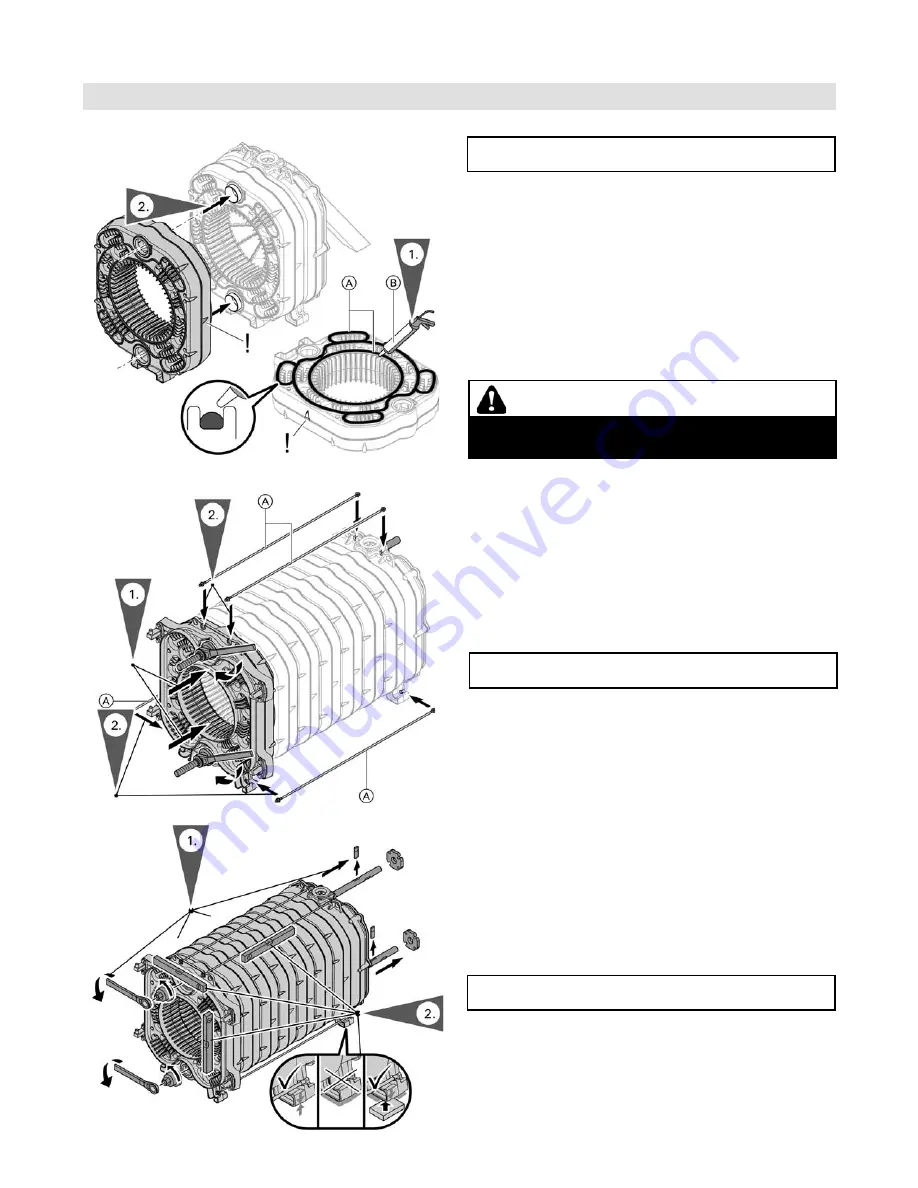

Cast Iron Section Assembly

(continued)

Set-up

1. Lay each section flat, gasket side facing up

A

.

Apply supplied “Soudal” silicone

B

into grooves

while the cast iron section is laying flat. The next

intermediate sections require sealing all passes,

as shown in Fig. 18.

2. Align the prepared intermediate section with push

nipples on the assembled section. Using a pry bar,

make sure that the push nipples are evenly inserted

into the incoming intermediate section.

IMPORTANT

During the compression procedure, draw in only one

additional section at a time to prevent leaks at the joints.

CAUTION

During the application of the silicone, ensure that the

work area is properly ventilated.

1. Loosen pressure nuts and remove draw tool kit.

2. Ensure that the heat exchanger block is level and

vertical on boiler base. All individual section legs

must properly rest on boiler base.

3. Please clean draw tool kit before crating, ensure that

all parts are included and crate is properly closed

before return shipment.

IMPORTANT

Only release the draw tool once the sections have been

joined with the tie rods.

IMPORTANT

All section feet must be firmly placed on the boiler base.

If necessary, shim section feet.

1. Prepare front section in the same way as previous

sections and align with heat exchanger block utilizing

the draw tool kit in the same fashion as before.

2. Tie rods with washers to top and bottom of heat

exchanger block. Do not overtighten.

Note:

Only hand tighten the nuts on the rods.

Never apply force.