Vitorond 200, VD2A Series Installation

5354 788 - 03

18

Set-up

Cast Iron Section Assembly

(continued)

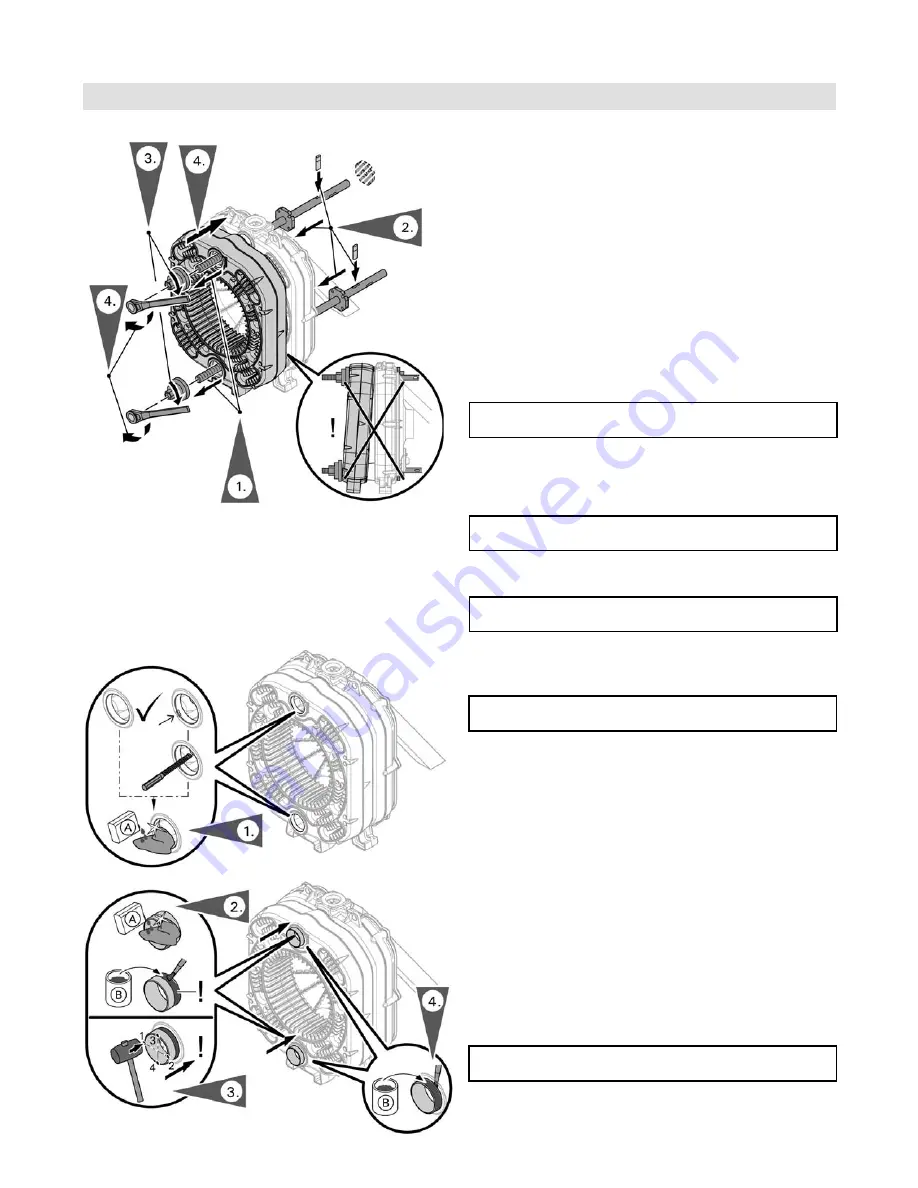

1. Insert the two main draw tool rods from the rear

section to the front section into the upper and lower

push nipple ports.

2. Slide pressure flanges onto the draw tool rods and

lock them with wedges, as shown in Fig. 16.

3. Attach pressure nuts and align both parallel to each

other (same thread depth) by utilizing the ratchet tool.

Ensure that all sections are aligned parallel to each

other before applying pressure.

4. Start to tighten evenly with ratchets. Once the push

nipple ports touch, do not apply further pressure.

Do not use excessive force if push nipple ports do not

touch.

Note:

Release and remove the compression tool

before fitting the next boiler section.

IMPORTANT

For all sections, clean nipples with solvent and apply

supplied linseed oil and graphite based sealant.

IMPORTANT

During the entire compression procedure, all threads on the

draw tool assembly must be properly lubricated with the

supplied linseed oil and graphite based sealant before use.

IMPORTANT

Each intermediate section has arrows on sides of the

casting. The arrows must be pointing up when laying flat

and during assembly they must point to the rear of the

boiler.

1. Check both nipple ports for burrs, and if necessary,

remove burrs with a half round file

A

. Never apply

file in an in-and-out motion on the nipple port, only in

a circular motion on the push nipple port sealing area.

Clean the nipple ports with solvent and dry properly.

2. Clean all push nipples with solvent, dry and paste one

half of the nipple with supplied linseed oil and graphite

based

sealant

B

(mix the graphite before using).

3. Insert push nipples into nipple ports and secure with

gentle hammer taps (wood or rubber mallet only).

Ensure push nipples are inserted evenly by tapping in

cross-wise

fashion.

4. Paste second half of the nipple with supplied linseed oil

and graphite based sealant

B

.

IMPORTANT

During the compression procedure, draw in only one

additional section at a time to prevent leaks at the joints.

IMPORTANT

To ensure no leaks, steel push nipples must be lubricated

by using linseed oil and graphite based sealant

B

.