Safety

9

Important Regulatory and Installation Requirements

(continued)

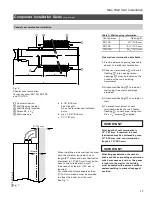

Table 1. Clearance to combustibles

Top

Front

Rear

Left

Right

Vent pipe

0”/mm

0”/0mm

0”/mm

0”/mm

0”/mm

0”/mm

Table 2. Recommended minimum service clearance

Top

*

Front

Rear

Left

Right

12”(305 mm)

28”(711 mm)

0”/mm

6”(152 mm)

0”/mm

For details refer to Vitodens 100-W or Vitodens 200-W Installation Instructions (as may be applicable).

For coaxial venting systems only:

In the event of flue gas leakage, the

boiler enclosure provides a tightly

sealed system on the inside of the

building. Escaping flue gas is fed back

into the combustion air intake,

preventing any flue gas from entering

the living area.

The venting system may be concealed

in a chase.

Minimum and maximum wall thickness

through which the horizontal vent-air

intake termination may be installed:

Minimum:

1”(25.4 mm)

Maximum:

19.6”(497.8 mm)

Vent-air intake system must be

properly installed and sealed.

CAUTION

Under certain climatic conditions some building materials may be affected by flue products expelled in close proximity to

unprotected surfaces. Sealing or shielding of the exposed surfaces with a corrosion resistant material (e.g. aluminum

sheeting) may be required to prevent staining or deterioration. The protective material should be attached and sealed (if

necessary) to the building before attaching the vent termination. It is strongly recommended to install the vent termination

on the leeward side of the building.

5

2

8

5

2

6

8

v

3

.8

The Vitodens 100-W and 200-W

boilers are NOT approved for

common-venting applications.

Do not attempt to common-vent the

Vitodens 200-W boiler with any

other appliance.

WARNING

Failure to ensure that all flue gases

have been safely vented to the

outdoors can cause property

damage, severe personal injury, or

loss of life. Flue gases may contain

deadly carbon monoxide.

WARNING

Summary of Contents for Vitodens 100-W WB1A-24

Page 78: ...78 5285 268 v3 8 ...

Page 79: ...79 5285 268 v3 8 ...