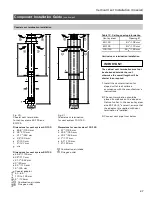

Direct Venting (Two-pipe System)

40

General Installation Information

Installation steps (outline)

Exhaust and combustion air piping

material

Use only the materials listed in table

30. entitled “Approved materials for

two-pipe system” on page 41 for

exhaust, combustion air intake pipe

and fittings.

H

Cut the pipe end square and remove

all burrs and debris from joints and

fittings.

H

If using CPVC special vent material

for exhaust vent pipe and

ABS/PVC/CPVC for combustion air

intake pipe, all joints must be properly

cleaned, primed and cemented. Use

only cement and primer approved for

the use with the pipe material. See

table 30. entitled “Approved

materials for two-pipe system” on

page 41 for approved solvent cement

material.

H

No low point is allowed in the

exhaust vent pipe system, unless a

proper drain pipe is used to allow

condensate to drain.

H

Route vent pipe as directly as

possible and with as few bends as

possible to the boiler.

H

Condensate must drain from the flue

pipe to the boiler. Ensure a suitable

gradient of at least 3º (approx. 2” per

3.3 ft. / 50 mm per 1 m).

H

Use a hacksaw and sheet metal snips

to cut pipes to length (if necessary).

Use a file to smooth rough edges.

Pipe must be round and not bent into

an oval shape.

When cutting pipes to length, debur

and clean pipes.

In conjunction with these

instructions, follow the installation

instructions supplied by the special

venting manufacturer.

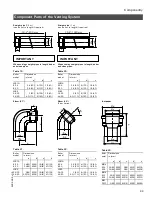

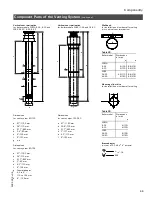

Viessmann Venting System

Instructions supersede the

instructions supplied by the

manufacturer.

H

All piping must be fully supported.

Use pipe hangers at a minimum of

48” / 1219mm intervals to prevent

sagging of the pipe.

H

The exhaust vent/air intake pipe and

fittings must be securely supported

by a support system suitable for the

weight and design of the material

employed. Contact your local vent

material supplier for more information

specific to your installation(s).

Ensure that the exhaust vent/air intake

pipes are properly supported. The

Vitodens boiler is not designed to

support the weight of the exhaust

vent/air intake pipe system.

H

Field supplied increaser fittings

(transition) should always be inserted

in vertical sections of pipe to prevent

accumulation of condensate in the

vent pipe.

H

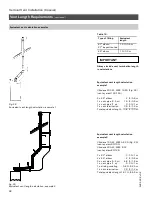

The total equivalent length specified

for a two-pipe system is the total of

the

combined

length of the exhaust

vent/air intake pipe system. Do not

exceed these maximum lenghts.

H

A maximum of five 90° elbows may

be installed in

combined

length of the

exhaust vent/air intake pipe system

(excluding termination elbows, tees,

hoods and couplings).

5

2

8

5

2

6

8

v

3

.8

For solvent cement and primer:

H

H

H

H

Use only in well ventilated areas

H

H

H

H

Do not use near flame or open fire

H

H

H

H

Use only the solvent cement and

primer appropriate for the venting

material being used

H

H

H

H

Solvent cements for plastic pipe are

flammable liquids and must be kept

away from all sources of ignition

CAUTION

Ensure that the entire venting

system is protected from physical

damage. A damaged venting system

may cause unsafe conditions.

WARNING

The venting system is approved for

indoor installations only.

Do not install the venting system

outdoors.

WARNING

IMPORTANT

IMPORTANT

Summary of Contents for Vitodens 100-W WB1A-24

Page 78: ...78 5285 268 v3 8 ...

Page 79: ...79 5285 268 v3 8 ...