28

VE46 Pipe Roll Grooving Tool

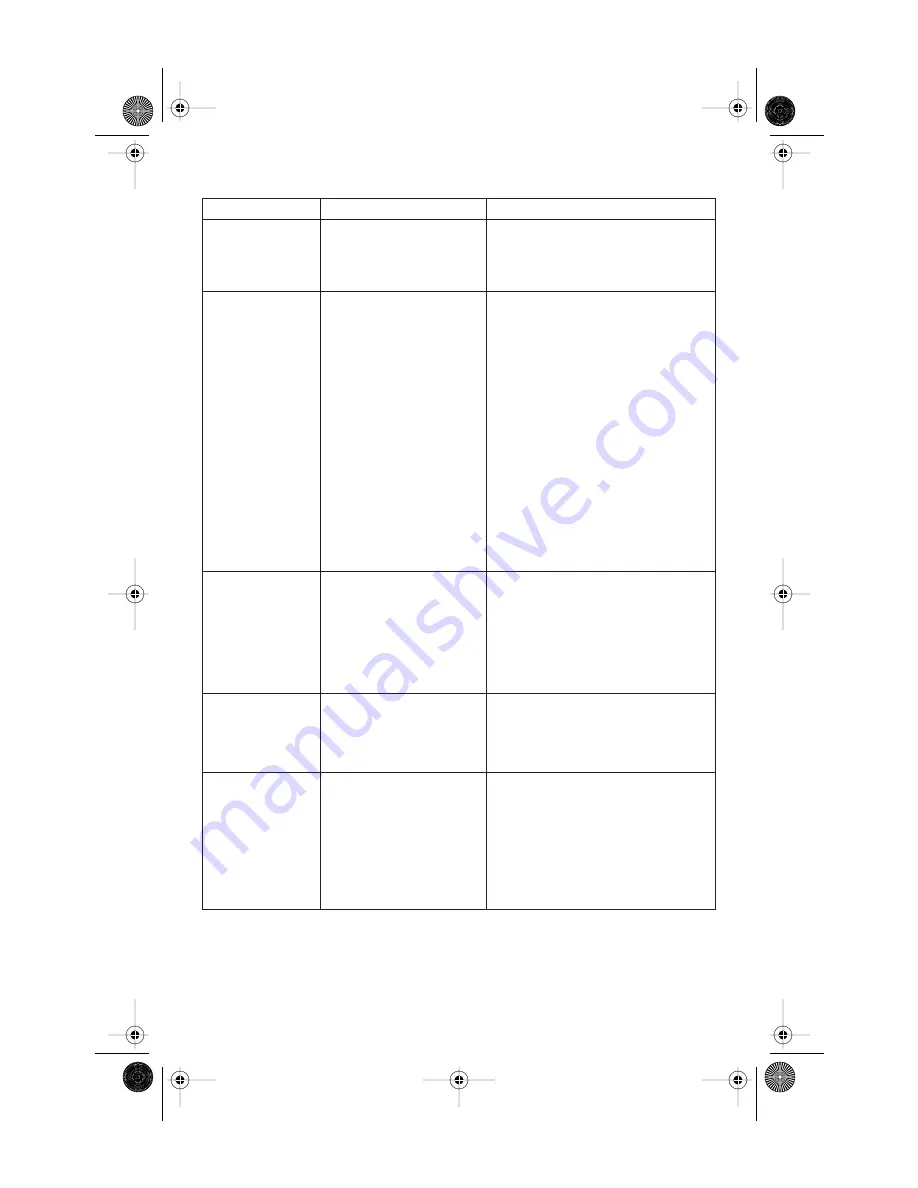

TOOLS INSTALLED ON A POWER DRIVE

Problem

Possible Cause

Solution

Pipe will not stay in the

grooving rolls.

Incorrect pipe positioning of

long pipe length.

Refer to the "Long Pipe Lengths" section on

page 15.

Roll set and pipe are not

rotating

clockwise

.

Flip the switch on the power drive to the

opposite rotation position.

Pipe stops rotating

during grooving.

Rust or dirt buildup is present

on the roll set.

Remove rust or dirt accumulation from the

roll set with a stiff wire brush.

Rust or dirt is excessively heavy

inside the pipe end.

Remove heavy rust and dirt from inside the

pipe end.

Worn roll set.

Inspect the roll set for worn knurls. Replace

the roll set if excessive wear is present.

Power drive has stalled due to

over-advancing the grooving

roll.

Make sure the pipe is supported. Release

the pipe by turning the feed nut

counterclockwise

, which will retract the roll

arm and grooving roll to the fully open

position. Refer to the "Grooving Operation

For Power Drive Setup" section on page 22

to start the grooving process again.

The circuit breaker has tripped

or a fuse has blown out on the

electrical circuit that supplies

the power drive.

Reset the breaker, or replace the fuse.

While grooving, loud

squeaks echo through

the pipe.

Incorrect pipe support

positioning on long pipe. Pipe is

“over-tracking.”

Re-position the pipe/ support. Refer to the

"Long Pipe Lengths" section on page 15.

Pipe is not cut square.

Cut the pipe end squarely.

Pipe is rubbing excessively on

the two pipe-end stops.

Remove the pipe from the tool, and apply a

light coating of grease to the two pipe-end

stops, as needed.

During grooving, loud

thumps or bangs

occur approximately

once every revolution

of the pipe.

Pipe has a pronounced weld

seam.

Grind the raised welds flush with the interior

and exterior pipe surfaces 2 inches (50 mm)

back from the pipe end.

Pipe flare is

excessive.

Pipe support is not adjusted

properly for a long length of

pipe.

Refer to the "Long Pipe Lengths" section on

page 15.

Tool is tilted backward while

grooving a long length of pipe.

Refer to the "Long Pipe Lengths" section on

page 15.

Incorrect pipe support

positioning of a long length of

pipe. Pipe is “over-tracking.”

Re-position the pipe support. Refer to the

"Long Pipe Lengths" section on page 15.

TM-VE46 1924 Rev_B.fm Page 28 Wednesday, January 19, 2005 8:59 AM