Danger to life due to damaged fork hooks!

Always observe the following:

– Check the upper and lower hook for cracks, deformation, and wear.

– Check the upper hook particularly in the area below the weld.

– If necessary, clean

Chapter 6.5 “Cleaning the fork carrier and fork arms”

Chapter 6.6 “Replacing the fork arms”

on page 43 the fork arm to do so.

Fork hooks are used for both power transmission and as the locking device.

Defective fork hooks (e.g., due to breakage) could cause the load to fall and

result in serious accidents.

Personnel:

n

Service specialist

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Special tool:

n

Measuring tool (caliper gage, feeler gage)

Danger to life due to deformed fork hooks!

Always observe the following:

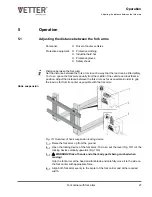

– Ensure that the hooks of the fork arm do not bend upwards by more than

0.079 inches (2 mm).

Fork hooks are used for both power transmission and as the locking device. If

the fork hooks are deformed due to material fatigue or overloading, the specified

nominal load capacity of the fork arms is no longer ensured. This could (e.g.,

due to breakage) cause the load to fall and result in serious accidents.

Damage to the

hooks

L

WARNING

Upward bending of

the hook

Deformation of the

hooks

L

WARNING

Maintenance

Checking the fork arms > Checking the suspension

Fork carrier with fork arms

34

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......