Danger to life due to deformed fork arms!

– Check the fork arms for deformation on a regular basis.

– Never use fork arms that exceed the maximum permissible height difference.

A difference in height between the fork tips of the mounted fork arms indicates

deformation of the fork blade or that a fork arm has bent upwards. If the height

difference of the fork arms exceeds a certain value

Δ

hmax (1.5% of the blade

length), the specified nominal load capacity of the fork arms is not longer

ensured. This could (e.g., due to breakage) cause the load to fall and result in

serious accidents.

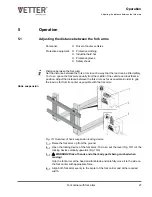

Fig. 16: Height difference, fork tip

1.

Calculate the maximum permissible height difference hmax:

Δ

hmax = (blade length [inches] / 100) x 1.5

2.

Mount the fork arms on the fork carrier and move them to a comfortable working

height.

3.

Place a level (or ruler) above both fork tips and, in doing so, put it flush against

the higher fork arm.

4.

Measure the difference h between the level and the lower fork blade at the fork

5.

If the measured height difference h exceeds the calculated value for hmax,

immediately ban any further use of the fork arm. Commissioning must only be

carried out after a successful repair or replacement.

Personnel:

n

Service specialist

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Deformed fork arms

L

WARNING

Wear/damage to the

fork tip

Maintenance

Checking the fork arms > Deformation of the fork arms

Fork carrier with fork arms

40

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......