49

General Sharpening Procedures

Viewed head-on, it would look exactly the same as the

gouge in

Drawing 1

on the previous page, except now

the larger-radius circle, not the smaller-radius circle,

would be the cutting edge (see

Drawing 7

below).

This shows that the need to be able to change direction

while cutting can be maintained only by having a decent

amount of the bevel on the outside of the gouge. But so

far we have been a bit infl exible in the analysis. Why

not change the amount of bevel transfer as we change

position on the gouge? Taking our earlier example where

we transfer 10° of the bevel to the inside so that we could

get a 15° attack angle, we see that we could eliminate

a lot of problems if we progressively transferred bevel

from the outside to the inside until it was totally in-

cannel at the top. Viewed head-on the gouge would look

something like

Drawing 8

on the next page. Raised to a

15° angle it would look something like

Drawing 9

.

This looks fi ne, but there are a couple of cautionary

notes. First, the upper edges are quite weak with only

10° included angles. Second, the gouge would not look

exactly like

Drawing 9

because we have been playing

fast and loose with geometry. In fact, if you had a gouge

ground like one in

Drawing 8

, raised to 15° it would

look more like

Drawing 10

.

There would still be some wedging action, because the

cutting edge of the gouge would still be inside the overall

profi le presented to the wood. The only way to grind the

gouge that would look exactly like

Drawing 9

would be

to have constantly changing bevel angles both inside and

out. The outside bevel would start at 15° and be gradually

reduced until it would reach 0° just as it disappeared. In

the same manner, the inside bevel would start at 10° and

continue to increase until it reached 25° at the top of the

gouge. It is exactly this sort of transitional bevel both

inside and outside that you should strive for when you

sharpen carving gouges.

You do not have to follow the above examples slavishly

when sharpening your carving gouges, but understanding

the principles involved lets you understand what is

happening when you are cutting wood. This prepares you

for the day when you switch from carving basswood to

carving cherry and wonder why your tools are suddenly

not working the way you expect them to. You might fi nd

that you have been depending on wood compression to

make a number of your best moves and that the much

more unforgiving cherry will not let you make those

moves. Just as you might have to increase the bevel

angles to keep edges from crumbling, you might have to

pay a lot more attention to relief angles so that you can

retain some maneuverability in cherry.

At the other end of the scale, if you are always going to be

carving softwoods of consistent density, all of the bevel

angles used in the examples are too great. You will get a

much better fi nish if you lower them to something closer

to 15° in total. The low bevel angles will give you a much

smoother fi nish with less fi ber pulling and crushing.

As a general rule, carving gouges are out-cannel and

pattern-maker’s gouges are in-cannel. Firmer gouges,

which are heavier than carving gouges and shorter than

patternmaker’s gouges, can be either. The primary use

for an in-cannel gouge is to make a straight groove of a

known radius. This is important in patternmaking, where a

shaft or similar machinery feature may have to fit into the

groove of the casting made from the pattern. The same

thing is true for millwrights who may have to make pillow

blocks for shafts and would want in-cannel gouges for

good control and a long straight cut.

The increased popularity of routers and the availability of

low-cost large-diameter bits have virtually elimi nated the

demand for in-cannel gouges. They are so rarely used

today that the term "gouge" is generally understood to

mean an out-cannel gouge. In fact, to many people the

term "cannel" is new to their vocabulary.

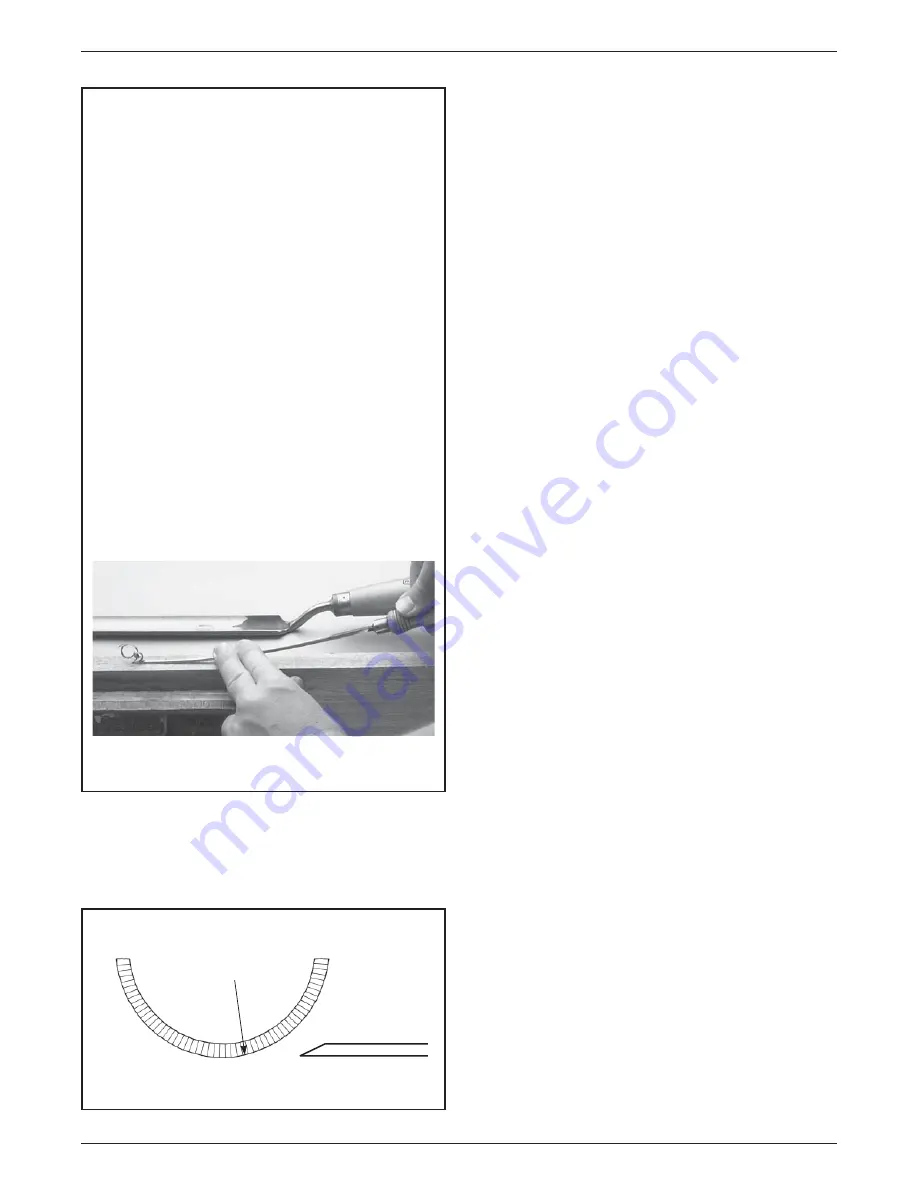

I bought the small in-cannel gouge being used in the

photo below at some long-forgotten tool sale. It is very

flexible and can be used just like a cranked-neck gouge.

With just a breath of back bevel on it (in this case, back

bevel means out-cannel) to compensate for the bend, it

will cut dead true on any flat surface. It would be a fairly

straightforward matter to make small gouges like this out

of drill rod; only the tip would have to be shaped.

In-Cannel and Out-Cannel Gouges

A slim, flexible in-cannel gouge can perform the same

function as a cranked-neck gouge.

7. Gouge viewed head-on (bevel inside)

In-Cannel Gouge

Cutting edge

Summary of Contents for Mk.II

Page 6: ...vi Veritas Mk II Power Sharpening System ...

Page 14: ...8 Veritas Mk II Power Sharpening System ...

Page 20: ...14 Veritas Mk II Power Sharpening System ...

Page 33: ...27 Exploded Assemblies Master Parts List 5 3 13 9 7 2 14 24 21 1 6 22 20 19 18 17 16 15 23 4 ...