46

Veritas

®

Mk.II Power Sharpening System

CARVING TOOLS

If you learn to sharpen carving tools well, you should

be able to sharpen anything. Virtually every hand-tool

shape considered in the rest of the book is included in

the standard range of carving tools. The wide variety of

shapes requires versatile grinding and honing systems.

At the same time, the diversity often precludes the use

of honing guides and demands the development of

freehand sharpening skills in any would-be carver.

To complicate the carver’s life, only a very few

carving tools can be purchased in a ready-to-use state.

Historically, carving tools were supplied with a basic

grind only. In Britain, until recently, a sharp tool was

considered to be a used tool. Since the supplier could

not know how the tool was going to be used or on what

woods, honing the tool would have required assumptions

in both areas. There was a higher probability of being

wrong than being right, so the tool was supplied with a

basic grind only.

Today, some carving tools can be purchased in a ready-

to-use state, which is a mixed blessing. On the positive

side, it indicates to the buyer the degree of sharpness

that can be attained, but on the negative side, it implies

that the provided shape is the correct one.

As with all tools, edge shape has to be married to

technique and the material to be worked; nowhere is

this more important than with carving tools. Whether or

not tools come from the store sharp or dull, you know

that they will eventually become dull anyway, so good

sharpening technique has to be developed by every

carver. Fortunately, modern technology has provided a

vast array of effective and fl exible sharpening materials

and systems, so the primary problem becomes one of

determining what shape you want, not so much how to

arrive at it.

Sharpening Gouges

The constant refrain of business consultants is to look

at products from the customer’s viewpoint to determine

whether or not the products are appropriate. While this

may sound a bit childlike, it is useful to do just that if

you want to understand exactly why you should shape

certain tools certain ways. You should look at them from

the viewpoint of the wood about to be cut.

Consider the standard carving gouge that you might buy

in an unsharpened state. You can almost be certain that

this tool is incorrectly shaped, so whether or not it has a

sharp edge is incidental.

Choosing a Bevel Angle

One of the fi rst things to be decided is a suitable bevel

angle. For light cuts in cedar, pine or basswood, a 15°

bevel angle would probably be adequate. For a bit

heavier work you would beef this up to 20°, and for very

hard woods you might want to make it 25°. If you are

going to be using a mallet on the gouge you may want

a 30° bevel or even 35° depending upon the nature of

the steel in the tool. As usual, you want the lowest bevel

angle consistent with edge retention, so let’s assume an

angle for general-purpose use of 25°.

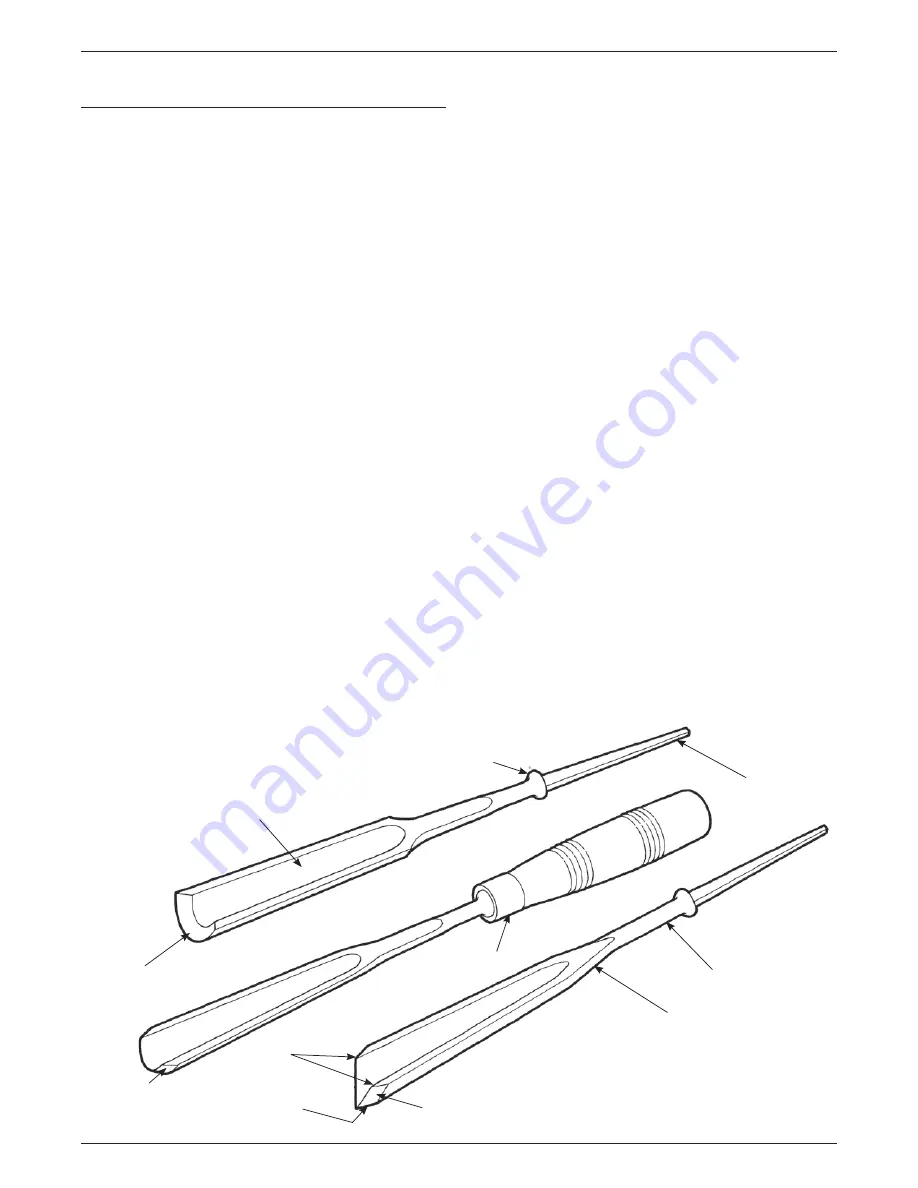

The Anatomy of a Gouge

Tang

Bolster

Flute

Wings

Heel

Bevel

Shoulder

Parting or ‘V’ Tool

Gouges

Neck

In-cannel bevel

Out-cannel bevel

Ferrule

Summary of Contents for Mk.II

Page 6: ...vi Veritas Mk II Power Sharpening System ...

Page 14: ...8 Veritas Mk II Power Sharpening System ...

Page 20: ...14 Veritas Mk II Power Sharpening System ...

Page 33: ...27 Exploded Assemblies Master Parts List 5 3 13 9 7 2 14 24 21 1 6 22 20 19 18 17 16 15 23 4 ...