Vega Light Control Systems

● Holland, Michigan 49424

2.4. STEP 4: Make electrical connections

•

Connect line voltage wires using wire nuts as shown in the wiring diagram in Section 3

➢

Strip wires appropriately for the wire nuts utilized, 3/8” for those included in the kit.

➢

The surge protector and power supply are universal voltage.

➢

The white wire may be either Neutral or Line.

➢

Green/Yellow wire is tied to grounding conductor.

•

Connect low voltage wires if they are separated during install.

➢

Plug connectors together when supplied with 2 pin Molex connectors between LED and driver.

➢

If loose wires connect White LED wire to positive driver lead (Red) and Gray LED wire to negative driver

lead (Black or Blue) using pre-installed Lever Nuts.

•

If photocell-controlled or remote controlled, connect Retrofit Kit to output of the control

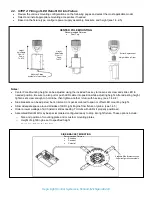

2.5. STEP 5: Secure fixture components

•

Secure fixture components and restore original light fixture sealing for water and insect control.

Notes:

•

Additional hardware maybe required to mount LED Retrofit Kit in fixture

•

Re-use screws previously holding HID ballast to fixture to attach Retrofit Kit when possible.

•

LED Light should be installed to maintain cooling clearance above heatsink (see 1.4.5)

•

For Type 3

, ensure “Street Side” of light engine faces the street

Note:

Screws used to mount LED module and power supply

in fixture are existing screws from previous HID system.

For a Post Top Fixture

SIDE BRACKET MOUNTING

Note:

Screws used to mount LED module and power supply

in fixture are existing screws from previous HID system.

For a Shoe Box fixture