7

11.03

Vedolux 30

Illustrations may differ from the actual product

Allowing for printing errors and errors on proofs

Installation

Function.of.accumulator.control

The accumulator control ensures that the boiler reaches a high

working temperature before it starts charging the accumulator tank.

It also prevents the return temperature to the boiler falling too low,

helping to minimise the risk of condensation in the combustion

chamber.

The charging pump of the accumulator system is controlled by a flue

gas thermostat.

Expansion.system

The boiler is connected to a vented or unvented expansion system.

The volume of the expansion vessel is dimensioned according to

the circumstances. The guideline values for volume are approx.

5 % of the total system volume for vented systems, or 13- 15 % for

unvented systems.

Vented

The distance between the top of the highest radiator and

the expansion vessel must be at least 8.2 ft in order to pre-

vent oxygen saturation of the water in the heating system.

The expansion vessel is connected in a continuous and

unisolatable rise from the boiler’s expansion connection.

To prevent damage occurring if the expansion system fails,

for example because of freezing, the boiler should be fitted

with a type approved safety valve, 21.8 psi.

Unvented In unvented systems, the boiler must be fitted with a type

approved safety valve, 21.8 psi, connected using an uniso-

latable pipe from the connection at the top of the boiler, as

well as a bleed valve.

The expansion vessel is best connected using ½” copper-

pipe, as shown in the diagram on the previous page.

The opening pressure of the safety valve is based on the

lowest maximum pressure that any system component

can withstand.

Coolin

g.coil.-.temperature.limiter

The boiler system must be equipped with a temperature limiter in

accordance with the applicable regulations.

The boiler has a cooling coil which, combined with a suitable thermal

valve, is used to prevent the boiler temperature exceeding 230°F if

the water boils. Follow the instructions of the va

lve manufacturer.

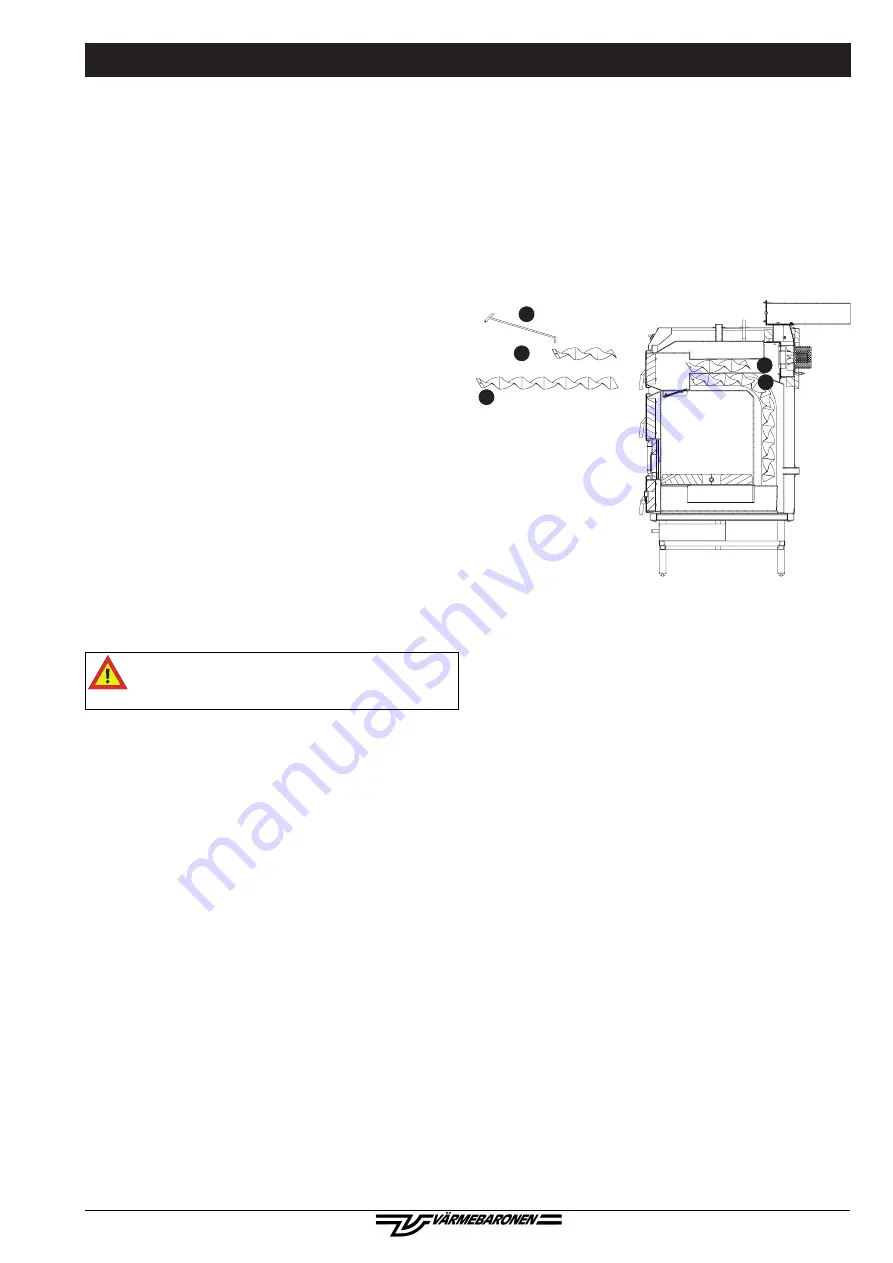

Turbulators

The five turbulators are installed in the flue gas pipes as shown in

the diagram. The purpose of the turbulators is to introduce turbu-

lence to the flue gases, causing more heat to be transferred to the

boiler water.

If the flue gas temperature falls too low (with a wide and long chim-

ney), there is a risk of condensation in the flue duct. To increase the

temperature, the three upper turbulators can be removed, or cut to

a length that produces a suitable flue gas temperature The draught

hatch is another way of reducing condensation problems.

Bracket.for.cleaning.tool

The bracket for the cleaning tool can be fitted to either side of the

boiler or any suitable place close to the boiler.

Draught.hatch

An extremely high chimney and/or strong winds can create a draught

that is strong enough to allow combustion with the fan turned off.

The solution is to install a draught hatch, which can reduce the

draught to 0.04 - 0.06 in. water.

Pellet.burner/oil.burner

The Vedolux 30 is primarily designed to be fired by firewood, but can

also be modified for pellets using a pellet burner.

When the pellet burner is used, the accessories supplied with the

pellet hatch set must be installed:

• Hatch, designed for the Viking Bio pellet burner.

• Cover plate with draught hatch, instead of the fan on the rear of the

boiler.

• Cover plates for the primary damper behind the plate on the front

of the boiler.

• Cover plate for the secondary damper.

It is possible to install an oil burner in the pellet hatch set. Fittings are

available.

Because of the risk of condensation you should monitor the flue gas

temperature. Check that the flue gas temperature is appropriate for

the chimney type.

Otherwise, follow the instructions of the burner manufacturer.

x 3

x 2

30

31

30

31

29