The wall has to be in such a condition that it can

support the weight of the heat pump with a full

tank of water (see page 6 for weight information).

When installing ductings the weight may not be

supported onto the heat pump.

The non-respect of these requirements will be

the reason of warranty exclusion and any cost on

material, animal and personal damages cannot

be forwarded to the manufacturer of this product.

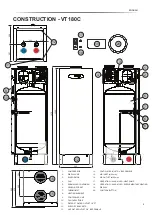

WALL MOUNTING THE HEAT PUMP (VT100C only)

INSTALLER ONLY

If the customer wish to wall mount the VT100C heat pump

please follow the below instructions carefully.

Wall brackets is not included, please order separately.

Free space*

67

310

1

57

20

Ø21

13**

71**

697

655

ENGLISH

12

* Free space is choosen either

by the customer, installer or due

to low free space in room.

** The brackets are not

positioned equally from center due to

(pos. 1, above drawing) the

holding bracket of the power cable.

This bracket may not be removed

due to its function of keeping the

power cable in position. Pulling the

wire without the holding bracket can

cause electrical hazard to the heat

pump.

Also note this bracket is to find on

VT180C. The same requirement

applies to this model.

The non-respect of this

requirement will be the reason of

warranty exclusion and any cost

on material, animal and personal

damage cannot be forwarded to the

manufacturer of this product.

Must be in correct level

Must be in correct level

Drawing is seen when you are

positioned in front of the heat pump.

Drawing is seen when you are

positioned in front of the heat pump.

Holes in the back panel of the heat

pump is big enough to ensure the bolts

are going into the foam when placing

the heat pump.