TECHNICAL INFORMATION

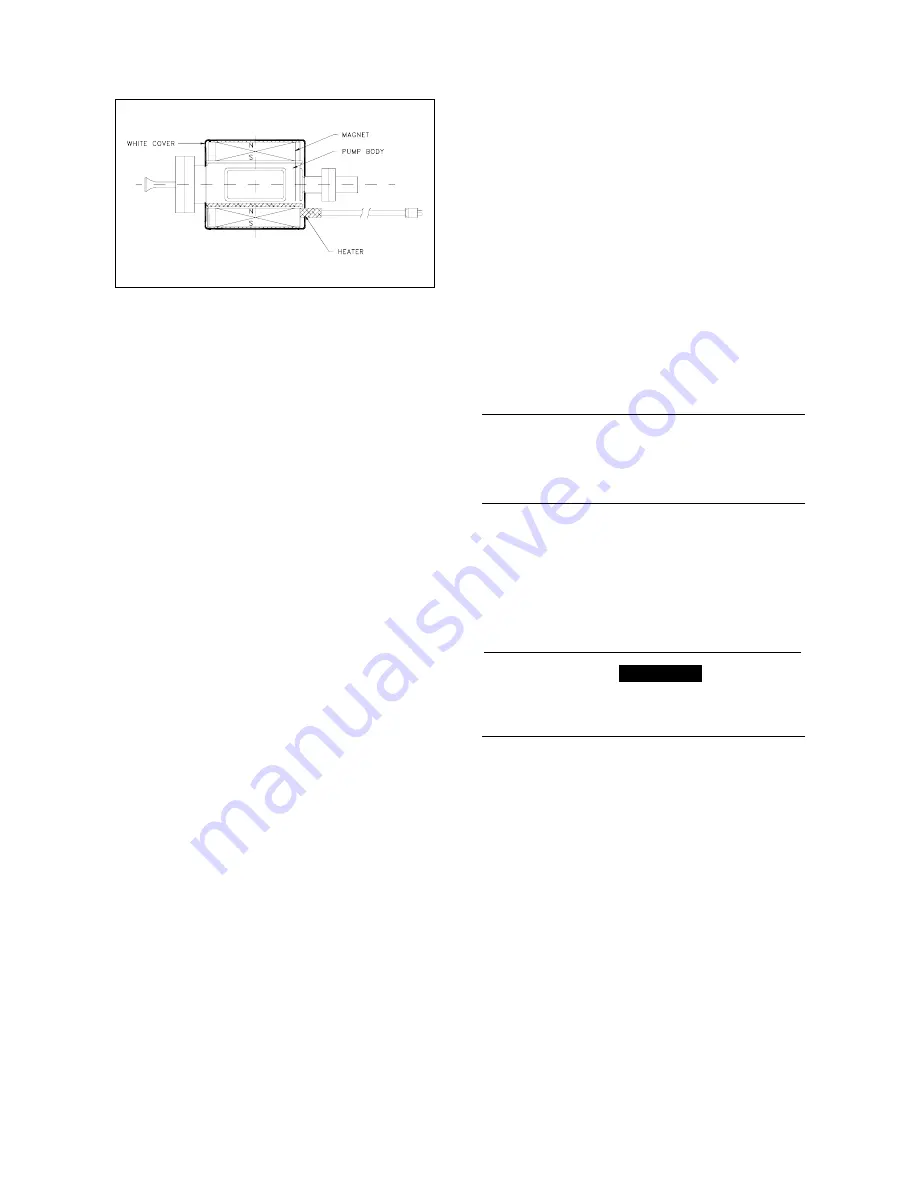

Fig. 18 - Heater element mounting

(cover removed)

HEATER REPLACEMENT

To replace the pump heaters, first remove the

faulty heater following, in the reverse order, the in-

structions of the paragraph “HEATER

INSTALLATION”, and then reassembly the new

heater following the instructions of the above men-

tioned paragraph.

BAKEOUT OPERATION

When a VacIon pump does not reach the desired

base pressure, and there are no leaks, it is neces-

sary to bake the system. This is done by heating

the pump and all the components in the system,

and is generally required to achieve base pres-

sures less than 10

-8

Torr (mbar).

1. Heat the pump body and the system with a

bakeout oven unit or heating strips to tempera-

tures between 150 °C and 250 °C (250 °C is

the maximum allowable for most bakeable high

voltage cables). This temperature is high

enough to degas the pump surfaces of water

vapor without damaging the magnet and high

voltage connector. Note that the system com-

ponents must be compatible with the bakeout

temperature. The heating must be approxi-

mately even on all surfaces or evaporated wa-

ter will condence on the colder surfaces

resulting in an incomplete bake and preventing

achievement of UHV vacuum pressure.

2. Leave the pump control unit on and monitor the

pressure. Varian recommends that current dur-

ing bake not exceed 10 mA; if this value is ex-

ceeded, turn the bakeout off and then on again

when low pressure is restored. To control the

heaters and to monitor the high pressure limit

during bakeout, an automatically controlled re-

lay may be used.

3. Bake the VacIon

Plus

pump for at least 24

hours. Longer bakeout periods are recom-

mended when the pump has been used with

heavy gas loads or when UHV pressure, 10

-9

Torr (mbar) or less is desired.

4. As the pump and system cool down to room

temperature, a drop in pressure should be ob-

served.

Note that the ion pump can be also baked when

switched off, into an external turbo pump through a

bakeable isolation valve. This method gives the

best vacuum performance.

Bakeout of VacIon pump with the integral

heaters

1. The integral heaters are to be powered with the

appropriate voltage. (Please refer to the

inscription on the heaters to apply correct volt-

age).

2. The integral heaters are designed to provide a

temperature of 250 °C to 300 °C when the

pump is wrapped in a 3-fold aluminum foil.

NOTE

A three-layer foil wrapping is advisable and suffi-

cient to achieve full bakeout/regeneration if the

standard European heaters (220 Vac) are oper-

ated at 240 Vac, thus preventing overheating.

3. Bakeout the VacIon pump for 24 hours. If the

pump is used in heavy gas load applications, it

is recommended to bakeout the pump for a

longer period.

4. Wait until the pump cools down to room tem-

perature and recovers its base pressure before

using it in the application.

,

WARNING!

Do not touch the pump during the heating and

cooling phases. The high temperature may cause

serious damage.

OPERATING PROCEDURE

1. Using a clean roughing pump, evacuate the

system to a minimum starting pressure per the

charts on pages from 10 to 12 for the type of

ion pump. 10

-4

Torr (mbar) or less is recom-

mended. A turbo-molecular roughing pump is

recommended.

2. When starting an ion pump, a slight increase

in vacuum pressure is normal as the internal

components are heated and outgassed. If

possible leave the roughing pump connected

to the system while starting the ion pump. This

will make the startup faster and easier.

3. Connect the control unit to a suitable power

source and switch the power on.

4. Switch on high voltage to the pump and ob-

serve the current and voltage. Fastest starting

is obtained using a high applied voltage, 7 kilo-

volts for example. The applied voltage may be

17

87-900-106-01(B)