60

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

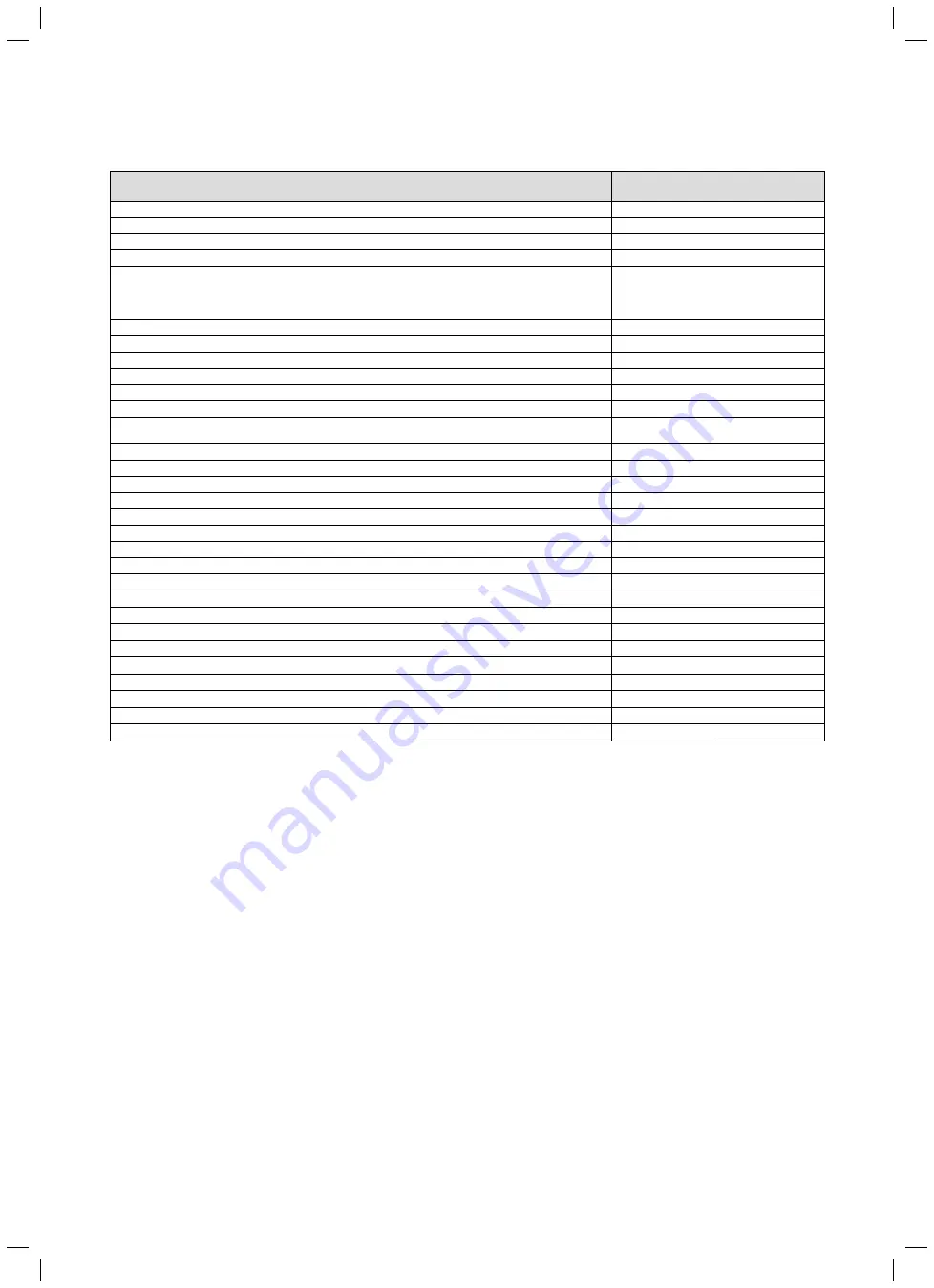

Maintenance work

Maintenance interval

Solar circuit

Check the system pressure at the gauge on the solar pump station.

Annually

Visually check pipe work and connections for solar fluid leaks.

Annually

Check the solar fluid discharge pipe is secure and canister is empty.

Annually

If necessary following above checks arrange for corrective work to be carried out.

Ensure system cannot go into stagnation. Avoid middle of day (cover collectors if possible).

Depressurise the system. NOTE: Drain fluid into suitable canisters.

Carry out any repairs to correct any leaks found.

Check the pH value of the solar fluid (with litmus paper, pH > 7.5).

Annually

Check the frost protection of the solar fluid (use the Vaillant solar fluid tester).

Annually

Check the operation of the solar pump.

Annually

Check the flow rate in the solar circuit is set correctly for the system.

Annually

Collector Array

Visual inspection of the collector, collector fastenings and connections.

Visual inspection only from suitable safe location.

Annually

Check the pipe insulation for damage and arrange repair if necessary.

Annually

Solar controller

Check and record solar gains. Reset as necessary.

Annually

Check the sensors are secure and temperatures correctly displayed (KOL1, SP1 and SP2).

Annually

Check settings are correct (see controller manual for details).

Annually

Check the time programme and temperature settings for auxiliary reheat are correct.

Annually

Cylinder

Check all connections to ensure that there are no leaks.

Annually

Check the temperature and pressure relief valve.

Annually

Check the expansion relief valve.

Annually

Check the charge pressure of the hot water expansion vessel.

Annually

Check water flow rates are correct (check and clean filters as necessary).

Annually

Ensure set temperatures are correct

Annually

Check the charge pressure of the expansion vessel, re-pressurise as necessary.

Annually

Check the function of the hot water thermostat mixer.

Annually

Fill in the service section of the Benchmark cylinder commissioning checklist.

Annually

Tab. 8.1 Maintenance checklist

8 Inspection and maintenance