Appendix

0020291544_01 Hydraulic Station Installation and maintenance instructions

53

J

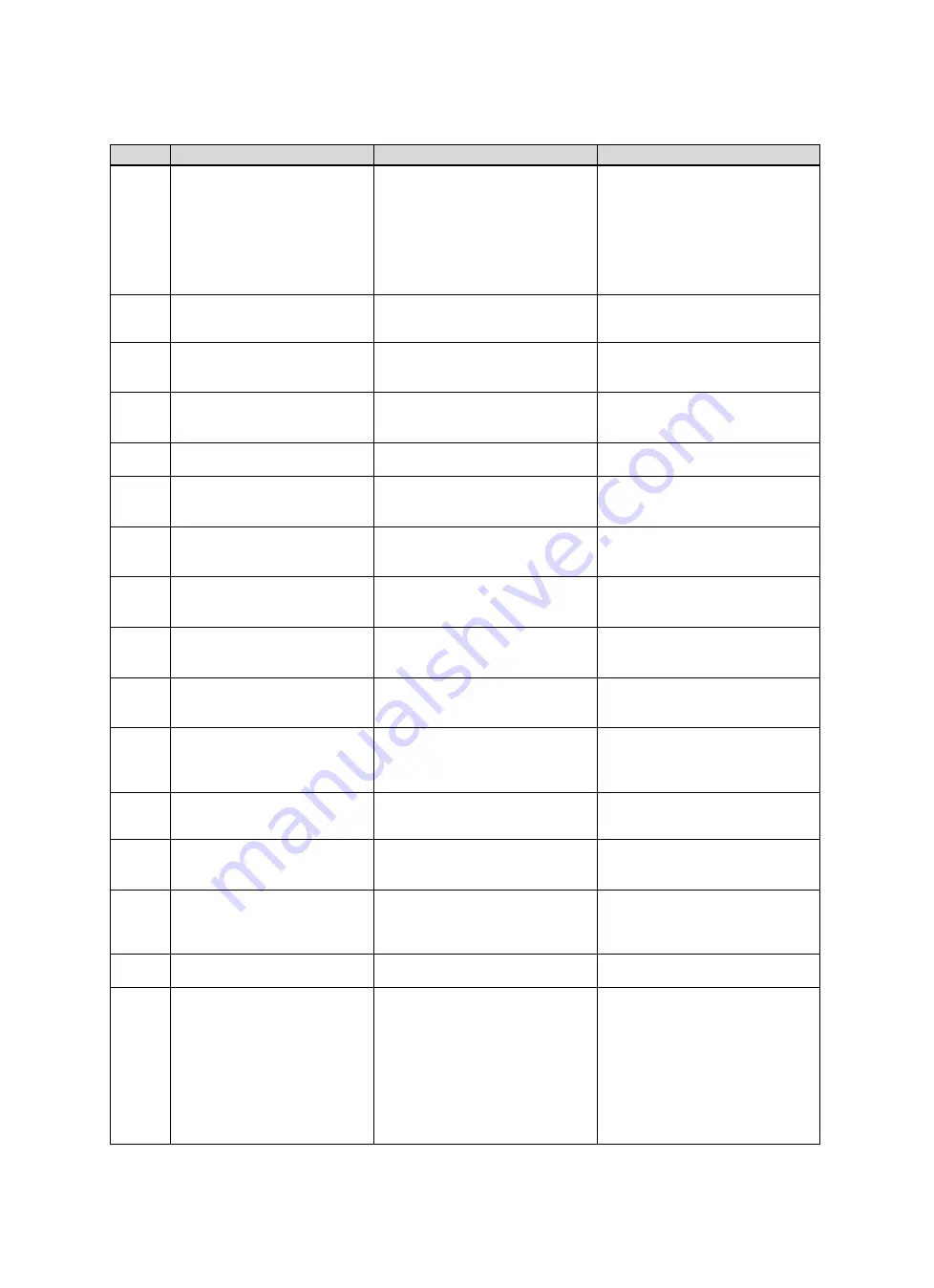

Fault codes

Code

Meaning

Cause

Remedy

F.022

Water pressure too low

–

Pressure loss in the building circuit

due to leakages or air pockets

–

Building circuit pressure sensor

defective

–

Check the building circuit for leaks

–

Top up with water, purge

–

Check the quality of the plug contact

on the PCB and on the cable har-

ness

–

Check that the pressure sensor is

working correctly

–

Replace the pressure sensor

F.042

Fault: Coding resistor

–

Coding resistor damaged or not set

–

Check that the coding resistor is

positioned correctly and, if required,

replace it.

F.073

Sensor fault: Build. circ. pressure

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.094

Fault: Vortex

–

Volume flow sensor not connected or

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.103

Fault: Spare part ident.

–

Incorrect control PCB installed on

the outdoor unit

–

Installing the correct PCB

F.514

Sensor fault: Compr. inlet temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.517

Sensor fault: Compr. outlet temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.519

Sensor fault: Building circuit re-

turn temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.520

Sensor fault: Building circuit flow

temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.526

Sensor fault: EEV outlet temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.546

Sensor fault: High pressure

–

The sensor is not connected or the

sensor input has short-circuited

–

Check the sensor (e.g. using an in-

stallation aid), and replace if neces-

sary

–

Replace the cable harness

F.582

Fault: EEV

–

EEV is not connected correctly or

there is a cable break to the coil

–

Check the plug connections and, if

required, replace the coil from the

EEV

F.585

Sensor fault: Capac. outlet temp.

–

The sensor is not connected or the

sensor input has short-circuited

–

Check and, if required, replace the

sensor

–

Replace the cable harness

F.703

Sensor fault: Low pressure

–

The sensor is not connected or the

sensor input has short-circuited

–

Checking the sensor (e.g. using an

installation aid), and replacing it if

necessary

–

Replace the cable harness

F.718

Fan unit 1: Fan blocked

–

There is no confirmation signal stat-

ing that the fan is rotating

–

Check the air route and, if required,

remove any blockages

F.729

Compressor outlet temperature

too low

–

The compressor outlet temperature

is lower than 0 °C for more than 10

minutes or the compressor outlet

temperature is lower than -10 °C

even though the heat pump is in the

operating characteristics.

–

Checking the high-pressure sensor

–

Checking that the EEV is working

correctly

–

Checking for condensate leaking

from the temperature sensor (under-

cooling)

–

Check whether the 4-port diverter

valve is in the intermediate position

–

Checking the refrigerant volume for

overfilling