VAG Operation and Maintenance Instructions • 9

Warning:

Open the threaded plug part 11 only by 3

turns maximum. The pressure is relieved via the drai-

nage groove in the thread. Maintenance work must not

be performed before this has been done.

6.3 Maintenance work and replacement of

parts

Maintenance activities are:

• Cleaning

• Removing deposits

• Reapplying a coating of corrosion protection (when necessary)

• Gasket replacement (when necessary)

• Air release orifice replacement (when necessary)

Inspection should include examination of:

• Damage and corrosion

• Movability of the float in the shut-off device

• Tightness

• Function

• Nozzle bores free from obstruction

• Visible deposits on floats and guide components

For shaft installation the following additional inspections are

required:

• Proper condition and cleanliness of the shaft structure

• Working order of the intake and outlet air of the shaft as well

as drain

• Condition of measures for thermal insulation

• Condition of additional protective measures against infiltration

of dirt, microbes and rain water in the shaft

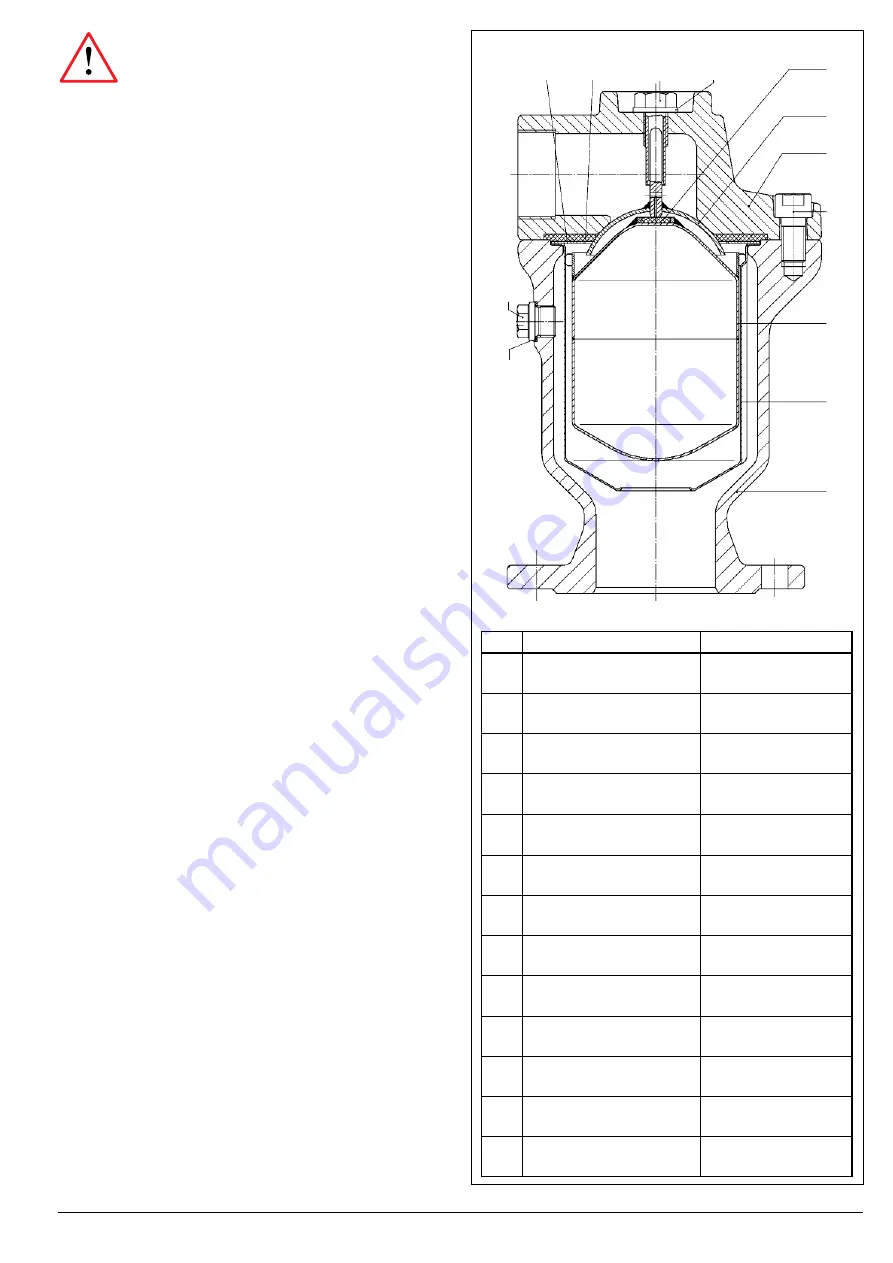

6.3.1 Design

The design view in Picture 14 is a partial overview of the following

descriptions of the work procedures. Spare parts with associated

part numbers are available in our document VAG KAT-E 1912.

6.3.2 Recommendations for the replacement

of parts

All parts should be changed as needed. The interval is oriented

towards servicing requirements.

For the sealings (part 3.2 and 8) replacement is recommended

every 5 years.

Replace the sealing ring (part 12) each time you open the threa-

ded plug.

Picture 14: Design

Item Name

Material

1

Body

EN-JS 1030

2

Cover

EN-JS 1030

3.1

Float

DN 50 / PN 16 plastic

> DN 50 stainless steel 1.4571

3.2

Sealing

EPDM

4

Shell body

1.4541

5

Shut-off device

1.4541

6

Lead srew

1.4305

7

Supporting Disc

1.4541

8

8A

Flatsealing

Gasket p=0,1 - 1 bar

EPDM

9

Cylinder Head Screw

A4-70

10

Disc

A4

11

Plug Screw

A4

12

Sealing ring

Centellen

7

11

2

1

8/8A

6

10

3.2

5

9

3.1

12

4