ENGLISH

42

OBSTACLE SENSOR

The PD18 control unit has two independent systems allowing

detection of whether gate movement is impeded by obstacles.

The first system is based on measurement of the current

absorbed by the motor, and is available on all control units: an

unexpected increase in current absorption indicates the presence

of an obstacle. The second system is based on measurement of

the rate of motor rotation and is only available if the encoder

option is present: a decreased rotation rate indicates the

presence of an obstacle.

PLEASE NOTE:

the amperometric sensor is disabled by default

and must be enabled by means of the

SenS

menu option; the

rate sensor is automatically enabled by enabling the encoder

option, and its sensitivity may be adjusted by means of the

S.EnC

menu option.

The detection of obstacles by means of the amperometric sensor

only occurs if the gate is moving at normal speed. If slowing

down has already started, the obstacle is not detected; this

situation is not hazardous since, during slow motion operation,

the motor pushes the obstacle with greatly reduced power.

Obstacle detection by means of the rate sensor is also conducted

during slowing down: the alarm threshold is automatically

lowered in order to allow movement at lower speed.

When a sensor trips, the gate is stopped and then sent in the

opposite direction for 3 seconds, in order to free the obstacle.

The subsequent Start command restarts movement in the

previous direction.

PLEASE NOTE:

if limit switches and slowing are disabled, when

the amperometric sensor trips, the control unit interrupts the

current opening or closing operation, without reversing the

direction of motion.

CONTROL UNIT

CONFIGURATION

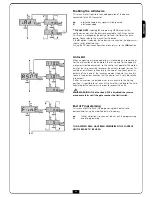

The configuration menu

-PrG

consists in a list of configurable

items; the display shows the selected item; pushing the wheel

downwards the following item is selected, pushing the wheel

upwards the previous item is selected. Pressing the wheel the

current value of the selected item is displayed and it is

possible to change it, if necessary.

The last item of the menu (

FinE

) allows to store the changes

made and to revert to the normal working of the control unit.

In order not to loose the own configuration it is compulsory

exiting through this menu item.

WARNING: If no operations are required for more then a

minute, the control unit exits from the programming mode

without saving the given information and changes will be

lost.

Keeping the wheel pushed downwards the configuration menu

items are quickly scrolled down until displayed the item

FinE

.

Likewise, keeping the wheel pushed upwards the items are

quickly scrolled down backwards until reached the item

t.AP

.

Like this, the beginning or the end of the list can be reached

quickly.

There are the following three kinds of menu items:

• Function menu

• Time menu

• Value menu

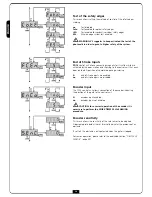

Function menu setup

Function menus allow selecting a function from among a group

of available options. When you enter into a function menu, the

current active option will be viewed; pushing the programming

wheel upwards or downwards it is possible to scroll down the

available options. The displayed option is started up pressing

the wheel; after this, back to the configuration menu.

Time menu setup

Time menus allow setting a function duration. When you enter

into a time menu, the current setup value will be viewed; the

display mode depends on the current value:

• times being lower than one minute will be viewed as follows:

Every time the wheel is pressed upwards (UP) the set time

increases of half a second; every time it's pressed downwards

(DOWN) the time decreases of half a second.

• Times between 1 and 10 minutes will be viewed as follows:

Every time the wheel is pressed upwards (UP) the set time

increases of 5 seconds; every time it's pressed downwards

(DOWN) the time decreases of 5 seconds.

• Times being more than 10 minutes will be viewed as follows:

Every time the wheel is pressed upwards (UP) the set time

increases of half a minute; every time it's pressed downwards

(DOWN) the time decreases of half a minute.

Keeping the wheel upwards (UP) the time increases quickly,

until reached its maximum. Likewise, keeping the wheel

downwards (DOWN) the time decreases quickly, until reached

0.0”

In some circumstances, setting the value to 0 means that the

relevant function is disabled, in this case, ‘

no

’ will appear

instead of

0.0”

.

The displayed option is confirmed pressing the wheel (MENU);

after this, back to the configuration menu.

Value menu setup

Value menus are similar to time menus; however, the setup

value can be any number. Keeping the wheel pressed upwards

or downwards the value increases or decreases slowly.

In the following pages the procedure to configure all the

parameters of the control unit

PD18

is shown step by step

Summary of Contents for FORTECO

Page 2: ......