E

N

G

L

IS

H

38

5 - CONTROL PANEL

5.1 - DISPLAY

When power is on, the control unit checks that display correctly

operates by switching on all segments for 1.5 sec.

8.8.8.8

.

Firmware version, e.g.

Pr I.2

, will be viewed in the following

1.5 sec.

Panel will be viewed upon completion of this test.

PLEASE NOTE: if the panel is off, the control unit should be

in ENERGY SAVING mode; press the OK key to turn it on.

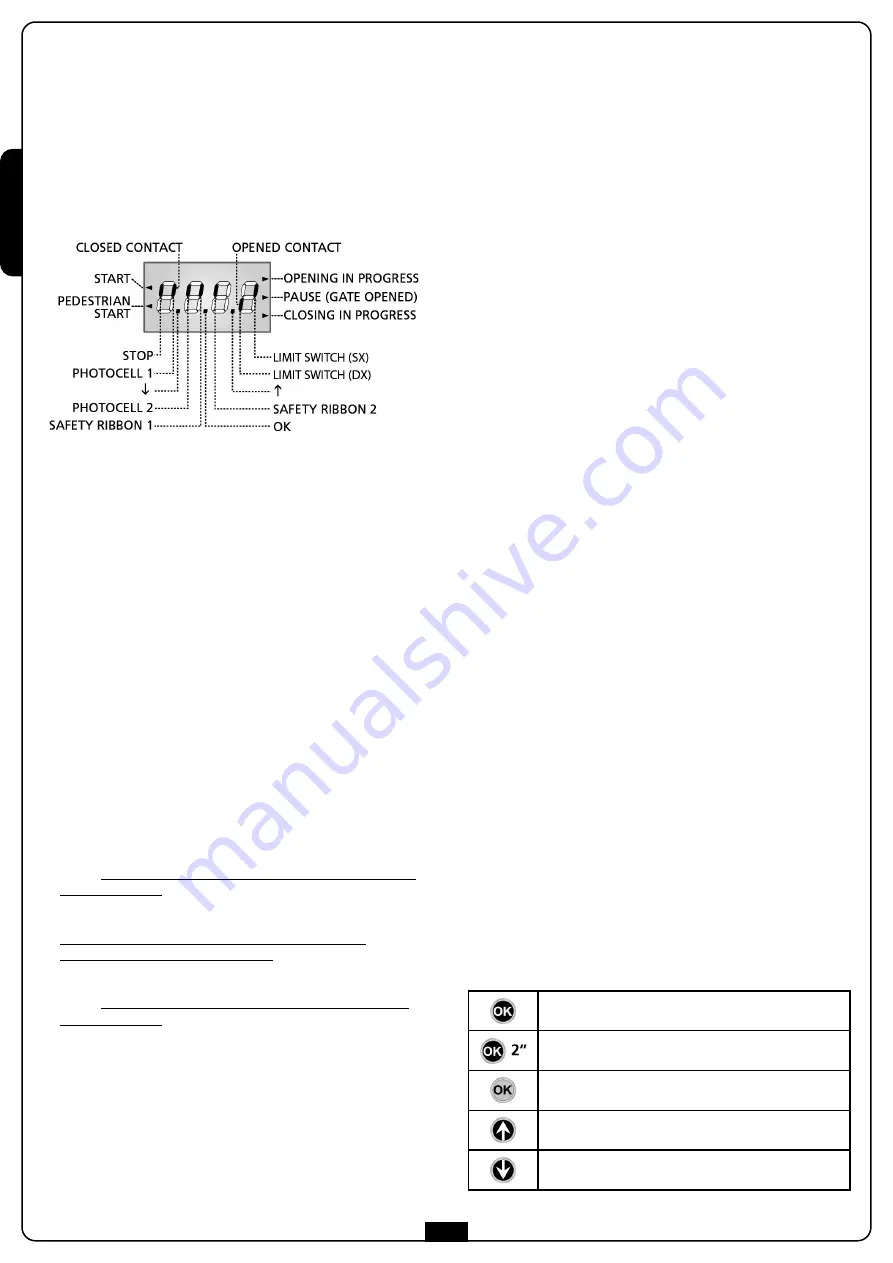

The control panel represents the physical status of the

terminal board contacts and of the program mode keys: if the

upper vertical segment is on, the contact is closed; if the lower

vertical segment is on, the contact is open (the above picture

shows an instance where the inputs PHOTO1, PHOTO2, EDGE1,

EDGE2 and STOP have all been correctly connected).

NOTE: if you are using an ADI module, other segments may

appear on the display, see the paragraph dedicated to the

“ADI INTERFACE”

Points being among display digits show the status of

programming push-buttons: as soon as a push-button is pressed,

its relevant point turns on.

The arrows on the left of the display show the state of the start

inputs. The arrows light when the related input is closed.

The arrows on the display right side show the gate status:

• The highest arrow turns on when the gate is into its opening

phase. If it blinks, it means that the opening has been caused

by a safety device (border or obstacle detector).

• The central arrow shows that the gate is on pause.

If it blinks, it means that the time countdown for the

automatic closing has been activated.

• The lowest arrow blinks when the gate is into its closing

phase. If it blinks, it means that the closing has been caused

by a safety device (border or obstacle detector).

5.2 - USE OF THE KEYS FOR PROGRAMMING

The control unit functions and times are programmed by means

of a special configuration menu, which can be accessed and

explored by using the 3 keys,

h

,

i

and

OK

, located on the side of

the control unit display.

PLEASE NOTE: Outside the configuration menu, pressing

the

h

key activates the START command, pressing the

i

key

activates the PEDESTRIAN START command.

There are the following three kinds of menu items:

• Function menu

• Time menu

• Value menu

Function menu setup

Function menus allow selecting a function from among a group

of available options. When you enter into a function menu, the

current active option will be viewed; you can scroll all available

options through

i

and

h

keys. By pressing the

OK

key, you will

activate the option viewed and you will return to the

configuration menu.

Time menu setup

Time menus allow setting a function duration. When you enter

into a time menu, the current setup value will be viewed; the

display mode depends on the current value:

Each time you press

h

key, current time value increases and each

time you press the

i

key, current time value decreases.

By holding down the

h

key, you can quickly increase the time

value, up to reach the max. value allowed for this item. Vice

versa, by holding down the

i

key, you can quickly decrease

the time value down to reach

0.0”

In some circumstances, setting the value to 0 means that the

relevant function is disabled, in this case, ‘no’ will appear instead

of

0.0”

By pressing on

OK

you will confirm the displayed value and

you will return to the configuration menu.

Value menu setup

Value menus are similar to time menus; however, the setup value

can be any number.

By holding down

h

or

i

keys, the value will increase or

decrease slowly.

By pressing on

OK

you will confirm the displayed value and

you will return to the configuration menu.

The main programming menus of the control unit are shown in

the next pages.

To go through the menus use the three keys “

h

,

i

and

OK

”

according to the following chart:

Press and release the push-button

OK

Keep pressed the push-button

OK

for 2 seconds

Release the push-button

OK

Press and release the push-button

h

Press and release the push-button

i