Inst

alla

tio

n Exa

mp

le

-

Mo

del

11.4

0C, 14

.40C

,

&

20.40C

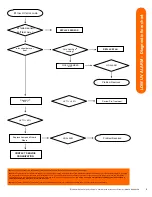

READ INSTALLATION CAUTIONS AND VERIFY

MINIMUM WATER QUALITY REQUIREMENTS BEFORE

PROCEEDING WITH INSTALLATION

GFI protected outlet

OPTIONAL

–

additional

pre-treatment as required,

Optional

Solenoid valve

5 micron sediment filter

–

minimum required pre-treatment

GFI protected outlet

UV detector

probe

UV Power Source

UV Disinfection

Chamber

Disinfected water to all

taps and appliances

IEC power

cord

Select a disinfection system mounting location where a potential leak will not

cause water damage. UVDynamics is not responsible for water damage. When the

disinfection system can only be located where water damage is a possibility, the

installation of a automatic leak detector / shut off device is highly recommended

©

COPYRIGHT 201

9

UVDynamics

- a Castle Circuits Inc. Business Group

All RIGHTS RESERVED

Cooling

Fan

Ball

Valve

Ball

Valve

Inlet

8