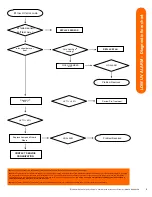

Lamp Spring

Part # 400354

Glandnut

Part # 400254

Quartz Sleeve

Model 11.40C Part # 400274

Model 14.40C Part # 400323

Model 20.40C Part # 400275

UV Lamp

Model 11.40C Part # 400270

Model 14.40C Part # 400158

Model 20.40C Part # 400271

UV Power UV Detect

Model 11.40C 120V Part # 400206

Model 11.40C 240V Part # 400230

Model 14.40C 120V Part # 400373

Model 14.40C 240V Part # 400496

Model 20.40C 120V Part # 400250

Model 20.40C 240V Part # 400497

IEC Power Cord

Part# 400114 120V

“O” Ring

Part # 400286

Outlet Port

Disinfection Chamber

Model 11.40C Part # 400666

Model 14.40C Part # 400310

Model 20.40C Part # 400612

Inlet Port

“O” Ring

Part # 400286

Glandnut

Part # 400287

UV Sensor Probe

Part # 400285

UV Sensor “O” Ring

Part # 400289

ColdSpot Fan

TM

Part # 400290

Mounting bracket

Part # 400108

CO

MP

O

NE

N

T I

DENTIF

IIER

-

Model

1

1.40C,

14.40C, &

20.40

C

6

Flow regulator insert

Model 11.40C Part # 400319

Model 14.40C Part # 400320

Model 20.40C Part # 400321

Retainer “0” Ring

Part # 400286

©

COPYRIGHT 201

9

UVDynamics – a Castle Circuits Inc. Business Group

All RIGHTS RESERVED