Installation and Maintenance Manual

READ AND UNDERSTAND ALL

INSTRUCTIONS BEFORE INSTALLING OR

USING THIS PRODUCT

TABLE OF CONTENTS

Safety Instructions

1

Application Overview

1

Water Quality

1

Installation Considerations

1

Installation Procedure

2

Disinfection Procedure

2

UV Power Source Features

3

Operating and Maintenance

4

Component Identifier

– model 8.40C

5

– models 11.40C,14.40C, & 20.40C

6

Installation Example

– model 8.40C

7

– models 11.40C,14.40C, & 20.40C

8

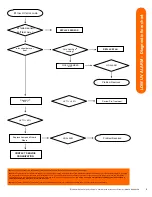

Low UV Alarm – Diagnostic Flow Chart

9

Specifications & Warranty

10

UV RADIATION HAZARD

NEVER OPERATE UV LAMP OUTSIDE OF THE UV

DISINFECTION CHAMBER

– EXPOSURE TO UV LIGHT CAN

RESULT IN SEVERE BURNING OF SKIN AND EYES

Safety instructions

– Please read carefully

DANGER

–

To reduce risk of electrical shock this system must be

grounded.

Connect your UV system to a grounded, GFI protected (3

pronged) receptacle (120V, 60HZ) and ensure that the lamp connector

ground wire is connected to the ground stud on the top of the disinfection

chamber.

Note:

Power source for applications outside of North America must

match requirements of the unit (eg. 240V, 50Hz).

Do not plug the unit in if any of the external surfaces or electrical parts

are wet. Condensation on the disinfection chamber is normal.

To avoid possible electric shock, special care should be taken since

water may be present near electrical equipment. Unless referred to in

these instructions, do not attempt repairs yourself. Contact the installing

dealer or manufacturer for service advice.

Do not operate this system if it has a damaged electrical cord or plug,

is malfunctioning, or has been dropped or damaged in any way.

Do not use this unit for anything other than its intended potable water

application. The use of attachments not recommended, approved, or

sold by the manufacturer/distributor may result in an unsafe condition.

Before any cleaning or maintenance, always disconnect the unit from

the AC supply voltage and de-pressurize the system.

Protect your unit from freezing. Drain all water from the unit if freezing

temperatures exist.

System must be installed in accordance with all applicable codes and

regulations.

If system indicates a failure state, water needs to be boiled before use

and the system and plumbing are required to be disinfected after system

failure is resolved.

This installation and operating manual is to be kept with UV

system.

APPLICATION OVERVIEW

UVDynamics UV disinfection systems certified to NSF/ANSI standard 55

are suitable for use on waters which are known to be contaminated.

This product uses a proprietary extended cold spot lamp design along

with an active temperature controlled cold spot cooling fan, resulting in

improved lamp output maintenance during stagnant hot water conditions.

The UV display indicates actual dose in mj/cm

2

at rated flow.

To insure trouble free operation of your UVDynamics UV disinfection

system it is important to ensure that your water source meets the

minimum water quality parameters specified.

Failure to meet minimum water quality standards may result in

excessive maintenance requirements or, in the case of UVT%

below 70%, may preclude the system from reaching the minimum

operating UV fluence (dose).

WATER QUALITY

Your UV disinfection system requires clean water for optimum

performance. You should only operate your unit if the source water

meets the following standards:

If your source water does not meet these water quality parameters,

additional pre-treatment will be required. Operation of this system with

water that does not meet these quality standards will increase the

occurrence of nuisance alarms, and result in increased maintenance and

more frequent lamp replacement. Operating the system with excessively

low UVT% (ultraviolet transmission percentage) will reduce UV intensity

to the point where operation of the system is not possible.

INSTALLATION CONSIDERATIONS

Select a disinfection system mounting location where a potential leak

will not cause water damage. UVDynamics is not responsible for water

damage. When the disinfection system can only be located where water

damage is a possibility, the installation of an automatic leak detector /

shut off device is highly recommended

UVDynamics disinfection devices are designed to be installed on the

cold water line only.

Cold water source must be connected to the inlet port only.

CAUTION:

reversing the flow direction by connecting the water source

to the output port could result in reduced disinfection performance and

improper operation of the flow regulator.

Turbidity

< 1 NTU

Suspended Solids

< 10 mg/L

Colour

None

Tannins/Other Organics

< 0.1 ppm

Total Iron

< 0.3 mg/L

Manganese

< 0.05 mg/L

Hardness

< 7 gpg

UVT%

> 80%

7

1

©

COPYRIGHT 201

9

UVDynamics – a Castle Circuits Inc. Business Group

All RIGHTS RESERVED