Page 3-27

Maintenance

3.17 - Torque Specifications

TL38 Service & Parts

Maintenance

Preventative Maintenance Table Key

Interval

Daily

=

each shift or every day

50h/30d

=

every 50 hours or 30 days

250h/6m

=

every 250 hours or 6 months

500h/1y

=

every 500 hours or 1 year

1000h/2y

=

every 1000 hours or 2 years

Y

=Yes/Acceptable

N

=No/Not Acceptable

R

=Repaired/Acceptable

Preventative Maintenance Report

Date : _______________________________

Owner : ______________________________

Model No : ____________________________

V.I.N No : _____________________________

Serial No :____________________________

Serviced By :__________________________

Service Interval :________________________

Battery

Check electrolyte level

Daily

System

Check battery cable condition.

Daily

Charge batteries.

Daily

Check specific gravity.

50h/30d

Clean exterior.

250h/6m

Clean terminals.

250h/6m

Hydraulic

Check oil level.

Daily

Oil

Drain and replace oil.

500h/1y

(ISO No.46)

Hydraulic

Wipe clean.

50h/30d

Pump

Check for hose fitting leaks

50h/30d

Check for leaks at mating surfaces. 50h/30d

Check mounting bolts for proper

50h/30d

torque.

Hydraulic

Check for leaks.

Daily

System

Check hose connections.

50h/30d

Check for exterior wear.

50h/30d

Change filter.

250h/6m

Emer.

Open the emergency lowering

Daily

Hydraulic

valves and check for proper

System

operation.

Control

Check switch operation.

Daily

Cable

Check the exterior of cable for

Daily

pinching, binding or cable wear.

Tyres /

Check tyre press. 4.45bar (65psi)

Daily

Wheels

Check for damage.

Daily

Check thread depth.

Daily

Check/torque nuts 100 Nm-74 ft lbs Daily

Platform

Check welds for cracks.

Daily

Deck and

Check condition of floor.

Daily

Guardrails

Check that securing bolts are

Daily

tightened.

Check drop bar on cage entrance. Daily

COMPONENT

INSPECTION OR SERVICES

INTERVAL

Y

N

R

Signature of Service Engineer

_____________________________

Slew

Grease slew gear.

50h/30d

System

Check slew motor for leaks and

50h/30d

mounting bolts for proper torque.

Check hardware and fittings for

250h/6m

proper torque.

Slew

Check torque on all bolts, 15 outer 50h/30d

System/

ring and 20 inner ring.

First Post

Retorque to 120 Nm (88 ft lbs).

Elevating

Inspect for structural cracks.

Daily

Assembly

Check hoses for pinch or rubbing

Daily

points.

Check pivot pins for damage.

50h/30d

Check pivot pin retaining rings.

50h/30d

Check elevating assembly for

250h/6m

bending.

Check component mounting for

250h/6m

proper torque.

Check fasteners for proper torque. 250h/6m

Lift

Check cylinder rod for wear.

50h/30d

Cylinders

Check pivot pin retaining rings.

50h/30d

Grease all fittings as section 3.4.

50h/30d

Chassis

Inspect for structural cracks.

Daily

Assembly

Check hoses for pinch or rubbing

Daily

points.

Entire Unit

Function check Emergency stop

Daily

switches at control boxes.

Perform pre-operation inspection.

Daily

Check for and repair collision

Daily

damage.

Lubricate.

50h/30d

Grease all fittings.

50h/30d

Check for corrosion - Remove and 250h/6m

repaint.

Outriggers

Check outrigger cylinders for

Daily

damage.

Check interlock switch function.

Daily

Lubricate.

50h/30d

Grease all fittings.

50h/30d

Tow Hitch

Check coupling for function and

Daily

wear.

Inspect breakaway cable for

Daily

proper attachment.

Grease all fittings as section 3.4.

50h/30d

Road

Check all trailer lights and

Daily

Lights

connecting plug.

Brake

Apply handbrake and check

Daily

function.

Check brake shoes for wear.

50h/30d

Test auto reverse function.

50h/30d

Adjust brake shoes.

50h/30d

Check handbrake and adjust.

250h/6m

Axle/ Hubs

Repack wheel bearings.

1000h/ 2y

COMPONENT

INSPECTION OR SERVICES

INTERVAL

Y

N

R

Summary of Contents for TL38

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL38 ...

Page 2: ......

Page 4: ......

Page 51: ...Page 3 28 Maintenance 3 17 Torque Specifications TL38 Service Parts NOTES ...

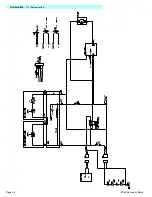

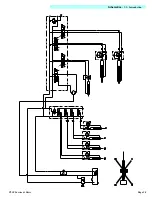

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL38 Service Parts ...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL38 Service Parts ...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL38 Service Parts ...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL38 Service Parts ...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL38 Service Parts Notes ...

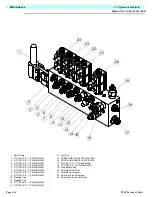

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL38 Service Parts ...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL38 Service Parts ...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly TL38 Service Parts ...

Page 84: ...Page 6 21 Illustrated Parts Breakdown Outrigger Cylinder Assembly TL38 Service Parts NOTES ...

Page 86: ...Page 6 23 Illustrated Parts Breakdown Electrical Assembly TL38 Service Parts ...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts ...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts ...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts NOTES ...