271001-UIM-A-0407

Unitary Products Group

25

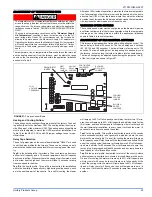

DIAGNOSTIC FAULT CODE STORAGE AND

RETRIEVAL

The control in this furnace is equipped with memory that will store up to

five error codes to allow a service technician to diagnose problems

more easily. This memory will be retained even if power to the furnace

is lost.

This feature should only be used by a qualified service tech-

nician.

The control stores up to five separate error codes. If more than five

error codes have occurred since the last reset, only the five most recent

will be retained. The furnace control board has a button, labeled "LAST

ERROR" that is used to retrieve error codes. This function will only work

if there are no active thermostat signals. So any call for heating, cooling

or continuous fan must be terminated before attempting to retrieve error

codes.

To retrieve the error codes, push the LAST ERROR button. The LED on

the control will then flash the error codes that are in memory, starting

with the most recent. There will be a two-second pause between each

flash code. After the error codes have all been displayed, the LED will

resume the normal slow green flash after a five second pause. To

repeat the series of error codes, push the button again.

If there are no error codes in memory, the LED will flash two green

flashes. To clear the memory, push the LAST ERROR button and hold it

for more than five seconds. The LED will flash three green flashes when

the memory has been cleared, then will resume the normal slow green

flash after a five-second pause.

FILTER PERFORMANCE

The airflow capacity data published in Table 16 represents blower per-

formance WITHOUT filters. To determine the approximate blower per-

formance of the system, apply the filter drop value for the filter being

used or select an appropriate value from Table 15.

NOTE:

The filter pressure drop values in Table 15 are typical values for

the type of filter listed and should only be used as a guideline. Actual

pressure drop ratings for each filter type vary between filter manufactur-

ers.

TABLE 15:

Filter Performance - Pressure Drop Inches W.C. and (kPa)

Airflow Range

Minimum

Opening Size

Filter Type

Disposable

Washable Fiber

Pleated

CFM

m

3

/min

in

2

cm

2

In W.C.

kPA

In W.C.

kPA

In W.C.

kPA

0 - 750

0 - 21.4

230

1484

0.01

0.00249

0.01

0.00249

0.15

0.03736

751 - 1000

21.25 - 28.32

330

2129

0.05

0.01245

0.05

0.01245

0.20

0.04982

1001 - 1250

28.33 - 35.40

330

2129

0.10

0.02491

0.10

0.02491

0.20

0.04982

1251 - 1500

35.41 - 42.48

330

2129

0.10

0.02491

0.10

0.02491

0.25

0.06227

1501 - 1750

42.49 - 49.55

380

2452

0.15

0.03736

0.14

0.03487

0.30

0.07473

1751 - 2000

49.56 - 56.63

380

2542

0.19

0.04733

0.18

0.04484

0.30

0.07473

2001 & Above

56.64 - Above

463

2987

0.19

0.04733

0.18

0.04484

0.30

0.07473