a) Mounting points

All compressors should be mounted firmly and securely to the engine bracket using

manufacturers’ standard specifications. The following chart outlines the minimum mounting

point utilisation for each Unicla model.

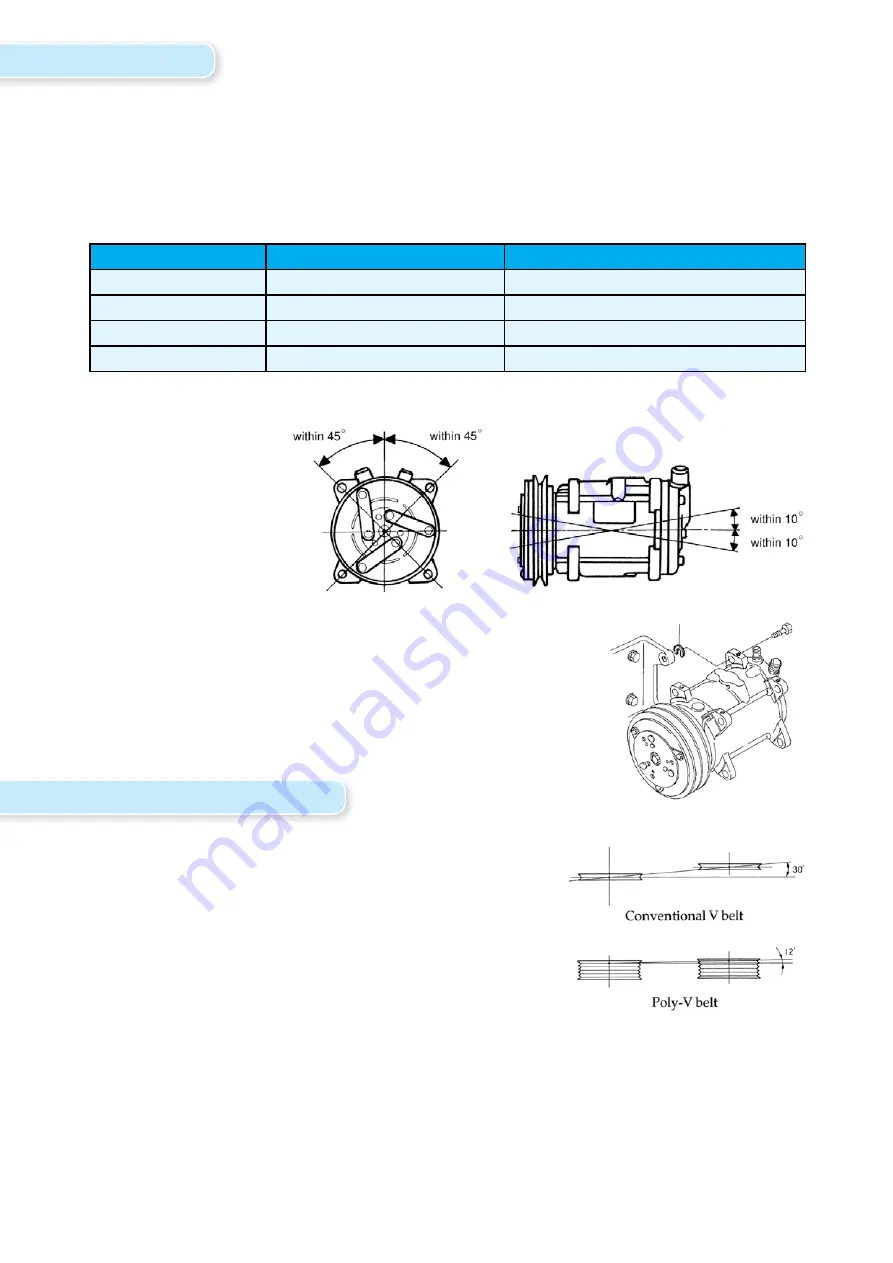

b) Mounting angle

The mounting angle

for each model must

be as follows:

c) Lug type mounting

When mounting Unicla UP series compressors (lug mount type)

there must be no gap between the bracket and the lug. This will

ensure additional stress is not placed on the compressor and noise

transmission is kept to a minimum. Universal sliding bushes or shims,

or Unicla shim kit part no 2900-000010 must be used as follows:

4. Belt alignment and tension

a) Alignment

The compressor clutch pulley must be in perfect alignment

with the drive pulley on the engine and any auxiliary idler or

adjusting system. Unacceptable alignment is shown in the

following diagram

b) Tension

Belt tension adjustment should be made so the belt is taut, but not to excess to cause excessive

bearing loads. Due to the pulsating load created by compressors, the belt tension must be

greater than for a normal steady load. The tension must be within the manufacturers’ guidelines

for the specific belt used to drive the compressor, or in the absence of this information, Unicla

recommends belt deflection of 10 - 20 mm /meter after tensioning, or 50kg of tension for most

applications. This tension must be checked again and tighten back to specification after 36-48

hours of initial operation.

3. Mounting

3.

Compressor type

Mounting description

Minimum mounting requirement

UC

Alternator or swing type

Three lugs

UP

Lug type

Four lugs

UX

Direct or bolt through type

Four points

UWX

Multiple direct mounting

Six points