16

9. Adjustment and repairs of the most important fertiliser distributor elements

NOTE:

Note: plastically crimped hose ends are not replaceable.

The replaced sealing ring will not be damaged only when it is placed in a groove on the

connection and at the same time in the supply socket. Do not screw in the connection too

deep. The groove in the connection (when screwed in) cannot protrude above the face of the

socket. In the first case, the sealing ring will be damaged by the socket thread and in the

second case

– by the lock nut. Wear of or damage to any of the sealing rings will cause

connection leakage (oil leaks from the system). To eliminate the leakage, replace the ring

(rings) with the new one (ones). The maximum oil flow rate at the hydraulic connections of the

tractor: 40 l/min.

NOTE:

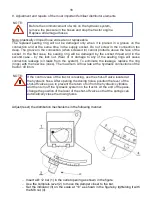

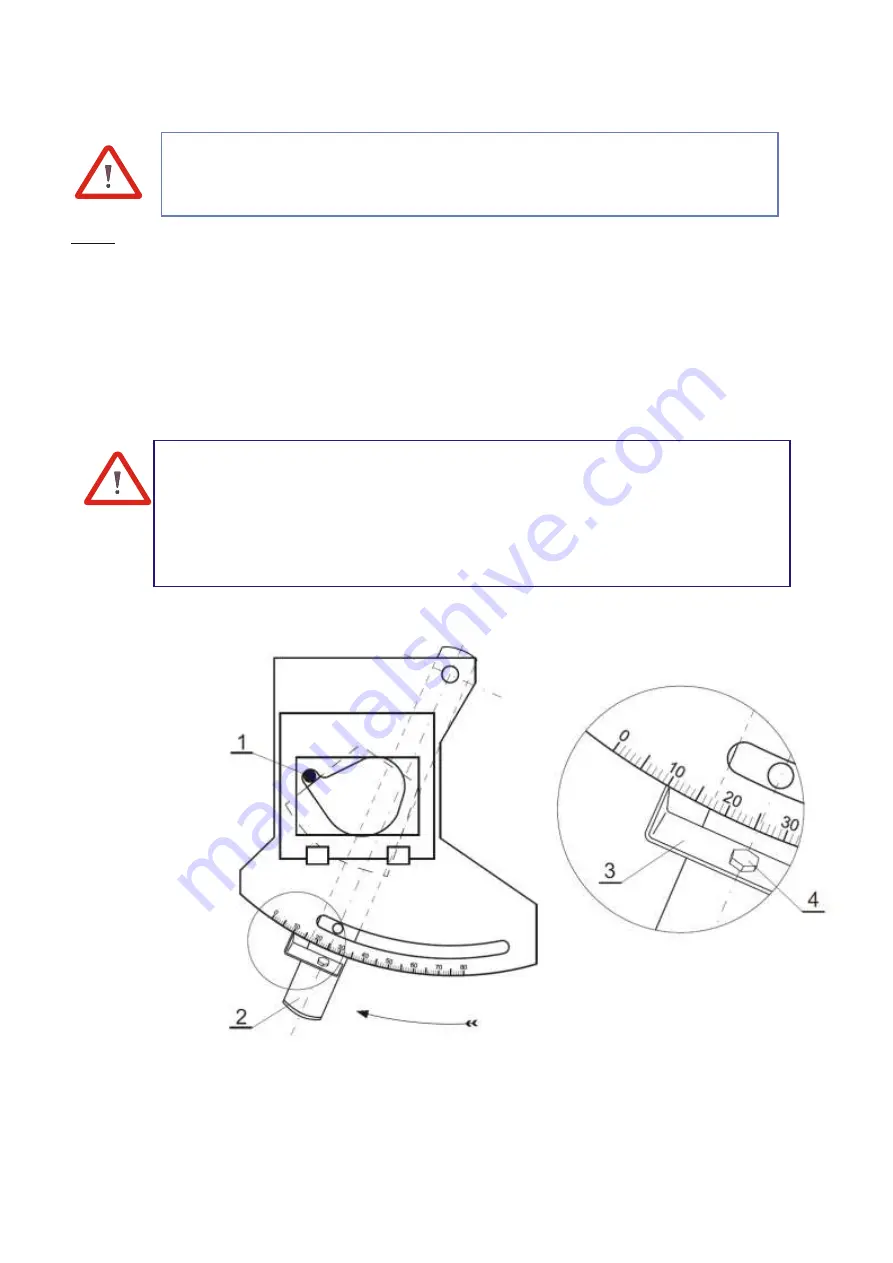

Adjust (reset) the distribution mechanisms in the following manner

:

−

Insert a Ø 12 bar (1) in the outlet opening as shown in the figure.

−

Use the complete lever (2) to move the damper closer to the bar.

−

Set the indicator

(3) on the scale at “10” as shown in the figure by tightening it with

the M6 nut (4).

1

2

3

4

Before the commencement of work on the hydraulic system,

remove the pressure in the hoses and stop the tractor engine.

Replace all damaged hoses.

If the control valve of the tractor is leaking, use the shut-off valve located at

the hydraulic hose. After opening the dosing holes, position the lever of the

shut-off valve so as to prevent the return of oil from the hydraulic cylinders

and then turn off the hydraulic system on the tractor. At the end of the pass,

change the position of the lever of the shut-off valve so that the springs can

automatically close the dosing holes.

Summary of Contents for MX

Page 3: ......

Page 43: ...40 5 4 2 3 1 Fig 6 Fig 7...