9

chimney. This is the task of the installer to control at the installation.

If the chimney is already equipped with a chimney damper this should be completely open at pellet firing. If

possible lock this in some way in open position.

We recommend installation of draft limiter (Back draft door)

The draft limiter shall at installation be adjusted by the installer of approx. -0,10/- 0.15 hPa under pressure.

The draft limiter also helps ventilate the chimney and minimize the risk of condensate problems. We

recommend that it is mounted on the flue pipe out from the boiler. It should be placed so that flue gas

measurements could be made before the draft limiter.

Flue gas thermometer

Provide your installation with a flue gas thermometer. Here you can easily see when the temperature rises

and it is time to clean the installation. Suitable temperature rising is approx. 40-50 degrees. But you should

also overlook the capacity of the boiler on hearth and convection part to take care of the ash amount in good

time. The tighter intervals give better fuel economy and efficiency.

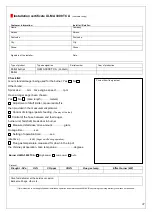

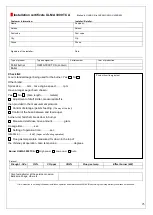

Flue gas analysis

At installation the unit should always be adjusted with a flue gas instrument and not only with help from the

human eye. When the burner is in place and has been trimmed in with a flue gas instrument a print of the

control measurements of the installer should be made. You should be able to read values like CO, O2, CO2,

combustion efficiency, draft, flue gas temperature etc. This analysis should also be made in writing in the two

forms that you find at the end of this manual. One of them you keep and one should be sent to ULMA AB in

Svenljunga. If this is not followed the warranty part of the burner is not valid.

Goal values:

CO2 : 11,5 -13,5 %

CO :10 - 300 ppm

NOx 80- 100ppm

O2 : 6,5- 8,5 %

hPa : -0,10 / -0,15 (draft)

Combustion efficiency (average): 90-95%

Fuel quality

The burner can handle most kinds of wood pellets between 6-8mm. At change of pellet deliverer the burner

should be adjusted with a flue gas instrument. We also recommend one flue gas analysis per year to have a

better control over the combustion.

Accumulator tank

It could be favorably to use an accumulator tank connected to the boiler since it gives longer operation times

on the burner and therefore better efficiency. But it is not financially sustainably to install an accumulator tank

in connection with the installation of the burner if you e.g. will not have a solar installation or choose to mount

the burner as a complement in a wood boiler.

Maintenance of the burner

At least 2 times per year the burner should be taken apart and the outer burner pipe separated from the

inner, since ash wastes is collected and sinter material that should be removed.

Replace the endstop

Demount the burner according to the pictures on page 16 and 17.

1.Get the endstop and the inner 2. Use a pliers or similiar to 3. Use a tool to lock the endstop

. chamber unit. press the endstop in the hole.

Then remount the reverse order as illustrated on page 16 and 17..