-6-

Lifting Points to Avoid:

Avoid lifting from the stainless steel threaded connections, control panel, pump, valves, or any of the pipe work

and fittings not mentioned above.

Maintenance Space:

Leave a minimum of double the width of the exchanger, either side of the unit, to allow for access to the

exchanger tie bolts, and to allow for removal of the heat transfer plates.

Leakage:

Gasketed Plate Heat Exchangers do have the potential to leak at some time during their life. Therefore, to

avoid damage to plant room floor, electrical conduits etc., we recommend that a drip tray is placed underneath

the plate pack.

Safety:

If the unit is to operate near personnel, we recommend that a metal spray shield is located over the

gasketed plate pack in case of “blow out”. This would avoid scalding. The surfaces of the unit, pump, valve,

and pipe work become hot during operation – ensure that adequate consideration is given to personnel to

protect them from burns when deciding upon the location of the unit.

Pressure – it is essential that the exchanger, as with all pressure containers, is protected from the effects of

any over pressurisation should a fault in the operation of the system arise. Provision of suitable pressure relief

devices such as relief valves, or bursting disks should be considered – positioned local to the exchanger, with

no control, or isolating valves between the device and the exchanger to “block the pressure path”.

Welding:

Do not weld near to or on the heat exchanger or associated components.

Primary Shunt Pumps:

The pumps rely on water for cooling and lubrication. Damage will be caused if the pumps are run on a dry

system.

DHW Shunt Pump:

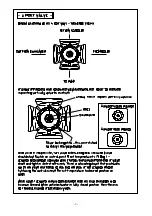

If a DHW pump is supplied loose, the direction of the pump must be so that the water flows into the top right

hand side connections (F2). Do not fit this pump until the unit has been installed in its final position. This pump

must be fitted with adequate supports so that no strain is put upon the heat exchanger connections.

Water Softener:

It is

essential

to treat / soften the DHW prior to heating to reduce the build up of scale in the heat exchanger.

Consult with a water softening specialist to determine the best method of treatment for the water in your area.

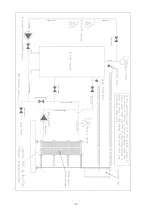

Water Connections:

Use two wrenches when attaching unions to the domestic water circuit threaded stub connections. One

wrench to be used to tighten the union & the other to prevent the stub end from rotating – this avoids damage

to the gasket inside the unit that seals against the back on the stub connection. Use a none hardening thread

sealant for best results. Threads are BS21 – taper, male. It is necessary to support the secondary pump and

the pipe work as the heat exchanger connections are not designed to accept any weight being imposed upon

them.