-17-

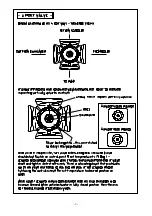

Actuator Replacement:

a) Switch off panel

b) Un-do central bolt holding actuator to valve stem, and pull off complete actuator assembly.

c) Remove small cross head screw holding actuator cover, remove cover, remove wire plug, and

note position of the 3 (some times 4) small dip switches on the printed circuit board.

d) Spray WD 40 or similar into valve stem bearing to lubricate valve and rotate a few times from left

to right.

e) Remove cover on new actuator, and set the dip switches the same as the old unit, plug in wires,

and refit actuator cover

f) Rotate control valve stem fully clockwise until it stops.

g) Switch on the panel, set temperature high to force the control system to rotate actuator to fully

open position, install actuator and tighten screw (NOTE – ensure that the back of the actuator

locks into the locating dowel protruding from the valve body) and then tighten the central screw.

Do not over tighten, and ensure that pointer is to the right (valve fully open), and that the actuator

knob is fully pushed in.

h) Alter the control Set Point to a low temperature – actuator should move until stops at fully closed

position. Then alter the control Set Point to a high temperature – actuator should move to fully

open position. If all OK then re-set control temperature to desired value.

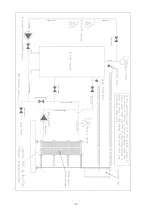

8. Maintenance:

Time interval:

Once a year as a minimum.

Performance:

Check temperatures and flows against commissioning data.

Plate pack:

Check the tightening dimension, and look for any signs of leakage from heat

exchanger.

Nozzles:

Check general condition, and for any signs of leakage.

Frame:

wipe clean all painted parts, and check surfaces for signs of damage - “touch up” if

necessary.

Bolts & bars:

Check for rust, and clean. Lightly coat threaded parts with molybdenum grease, or a

corrosion inhibitor (ensure that no grease, etc. falls onto the plate gaskets).

Electrical:

Check the security of all electrical connections and inspect the wiring for damage.

Actuator/valve:

Spray WD40 or similar into valve spindle where it enters the valve..

9. Spare Parts:

To help identify the unit, it is necessary to quote the serial number as given on the nameplate. Replacement

parts and other information can be obtained from:

UK Exchangers Ltd

Unit 55, Stilebrook Road, Olney, Buckinghamshire, MK46 5EA

Tel : 01234 244320 Fax : 01234 714978

E-mail:

Web:

www.uk-exchangers.com