-11-

Once all times are set the clock must be put into AUTO mode by repeatedly pressing the CH A MANUAL

key and CH B MANUAL key until the indicator bar on the display is above the word AUTO for both

channels.

Reviewing the existing program can be done be done by repeated pressing of the TIMER key. When done,

press the CLOCK key to return to run mode.

Timed operation can be overridden by pressing the MANUAL key to move the indicator bar on the display

to the desired position (ON, OFF or AUTO). Timed operation will not resume until the indicator bar is

repositioned above the word AUTO.

All time clock adjustment can be done with the panel turned off.

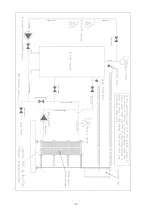

Table showing on days for DAY key settings (X=on)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Mon

X

X

X

X

X

X

Tue

X

X

X

X

X

X

Wed

X

X

X

X

X

X

Thur

X

X

X

X

X

Fri

X

X

X

X

X

Sat

X

X

X

X

X

Sun

X

X

X

3. Shutting down the Exchanger for Maintenance:

Shut down:

Switch panel “OFF” at main isolator.

Allow unit to cool, close isolation valves, and drain heat exchanger.

Tools:

Ratchet spanners and ring or open-ended spanners, plus light machine oil. M24 (36mm

across flats)

Procedure:

•

Ensure the control panel is isolated and all isolation valves on the pipe work are closed.

•

Allow unit to cool, and drain exchanger.

•

Release all pressure from inside of exchanger.

•

Lightly oil the tie bolt threads down either side of the exchanger.

•

Undo the clamping bolts uniformly - keep the frame plates as parallel as possible during this

operation.

•

Push / pull back the mobile frame plate away from plates pack & secure if necessary.

•

Separate heat transfer plates carefully, avoiding damage to gaskets.

Use gloves to handle the plates - the edges can be sharp.

4. Cleaning of the plates:

Safety:

Wear gloves & eye goggles when using cleaning detergents.

Brushing:

Use nylon or other types of “soft” scrubbing brushes with detergent.

Never

use a metal

brush, steel wool, or sand/glass paper.

Detergents:

Consult a cleaning specialist for a suitable choice of detergent. Ensure that all detergents

used are compatible with the plate and gasket material before use.

Plate material:

316 stainless steel

Gasket material:

Nitrile rubber, or EPDM