-16-

Trouble Shooting – continued:

g ) Check for binding / seizure – remove actuator (see actuator removal section) and then try to

rotate valve stem – you can use grips on the end of the stem as an aid but make sure that

the stem is protected from damage from the grips. The valve should rotate freely through out

the range of travel. Sediment build up can block the action of the valve and this rotating action

can some times be enough to free the component. If binding persists then isolate the unit,

shut down, and drain primary circuit. The inner parts of the valve can be removed without

taking the complete valve off the pipe work:

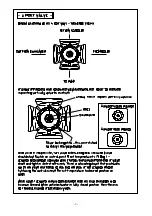

Cast iron valve type – loosen the 4 bolts on the side of the valve body and pull body back

the side panel. This may require a lever, but try to avoid damage to the sealing face.

Inspect, clean and lubricate or replace with new components. If it looks as though the

paddle is binding against the valve body then the paddle then any “proud” / high points

can be shaved down by the use of wet and dry, or emery, paper.

Brass valve type, rotate the silver disk until the lugs on the disk are no longer underneath

the brass noggins and then pull out the stem and valve paddle – there is a sealing O-ring

which needs to be protected from damage. If the paddle is tight to remove then replace the

central bolt into the stem and use the bolt to aid in pulling out the paddle part of the valve.

If it looks as though the paddle is binding against the valve body then the paddle then any

“proud” / high points can be shaved down by the use of wet and dry, or emery, paper.

A possible remedy without taking out valve inners may be to spray lubricant (such as

WD40) onto valve shaft bearing (see section on control valve in Section 1 at beginning of

manual) and then locate the stem a few times to work in the lubricant. If the pressure of the

primary circuit is too high then it can be greater than what the primary shunt pump on the

exchanger control loop can pump against. If this is the case, the primary shunt pump fails to

pump back into the return loop of the main primary circuit as it is effectively “fighting” against

the pressure of the primary circuit. The primary circuit pressure must be reduced to allow to

the shunt pump to circulate water through the exchanger.

Primary or secondary Pump(s) fails to operate:

Possible Causes:-

a) Circuit breaker tripped or set to “off” - Check circuit breakers inside panel .

b) If pump tripped out of a fault then this could indicate a too high a Current – if the unit is new

then check the direction of the pump rotation and check to see if the pipe work has been

connected correctly – the over load setting can be adjusted – contact an electrician to

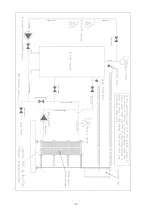

undertake this work. The wiring diagram can be referred too to find the location of the overload

and the factory setting. There is a scaled dial on the overload which can be rotated to

increase/decrease the overload current – caution – too high an over load setting reduces the

protection on the pump.

c) Pump motor burnt out or faulty – contact the Sales Office for replacement parts.