Part # 4518632 (02/19/08)

Page 9

OPERATION

continued

Lighting Instructions

For specific models see “Lighting Instructions” on the inside

of fryer compartment.

(

Frypot must be filled before lighting)

.

1. Turn thermostat knob to the frying temperature. The

thermostat knob is located inside the compartment in

the front of the frypot.

2. Open the fryer door and turn the combination safety

valve knob to the PILOT position.

3. Push the knob in, light the pilot and continue to hold

knob in for about sixty seconds after the flame has been

lit.

4. Turn valve knob counter-clockwise to ON.

5. Main burners will now light and will be controlled

automatically by the thermostat

NO

OFFP

I

L

O

T

NO

OFF

P

I L

O T

NO

OFF

P

IL

OT

AUTOMATIC VALVE KNOB

PILOT POSITION

AUTOMATIC VALVE KNOB

ON POSITION

AUTOMATIC VALVE KNOB

OFF POSITION

NOTE: Fryer cannot be shut off at the thermostat.

Thermostat used only to control temperatures.

Stand By

1. Turn fryer gas valve knob to “PILOT” position.

2. Put frypot cover in place.

Complete Shut Down

Turn gas valve knob clockwise to pilot position, DEPRESS

knob, slightly clockwise, release knob and continue turning

clockwise to OFF.

Safety Concerns

WARNING: The operator should be aware of the

HAZARDOUS NATURE, inadvertent splashing and spilling

etc., and RESULTANT CONSEQUENCES, personal burns,

fires, slipping on spilled liquid etc., when moving the fryer

with liquid in the vessel. If the fryer is to be moved, it is

recommended that the liquid in the vessel be cooled to

room temperature and removed from the vessel.

To assure you of maximum protection and performance

your US Range Fryer is equipped with the best and most

reliable controls and safety devices available. The operation

thermostat will regulate frying compound temperatures to

close tolerances in a range between 250°F and 375°F.

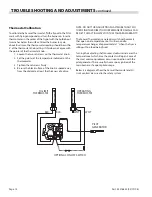

If for any reason the pilot should be extinguished the

combination safety valve will close off the gas flow to the

main burners and pilot burner. As an additional safety feature

this valve prevents gas from flowing to the main burners

when the pilot is being ignited.

On all units, due to the high rate of heating, and high limit

control device is provided as standard equipment. If for

any reason the frying compound temperature exceed the

maximum dial temperature the entire fryer will turn OFF at

450°F. If this should occur, have qualified service technician

check the system. FOR NO REASON SHOULD THIS HIGH LIMIT

DEVICE BE BY-PASSED!

Optimum Operation Tips

One of the most important considerations in the profitable

use of a fryer is the choice of the frying compound used. A

better frying compound will actually cost you less, because

it lasts longer than the lower grades and produce fried foods

with superior taste and appearance. There are numerous

high-grade products available and you are strongly urged to

use them.