111

107672-01- 7/17

XII. Operation

E. Boiler Sequence Of Operation (continued)

3. Status Screens (continued)

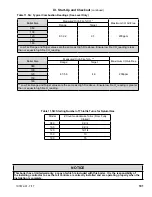

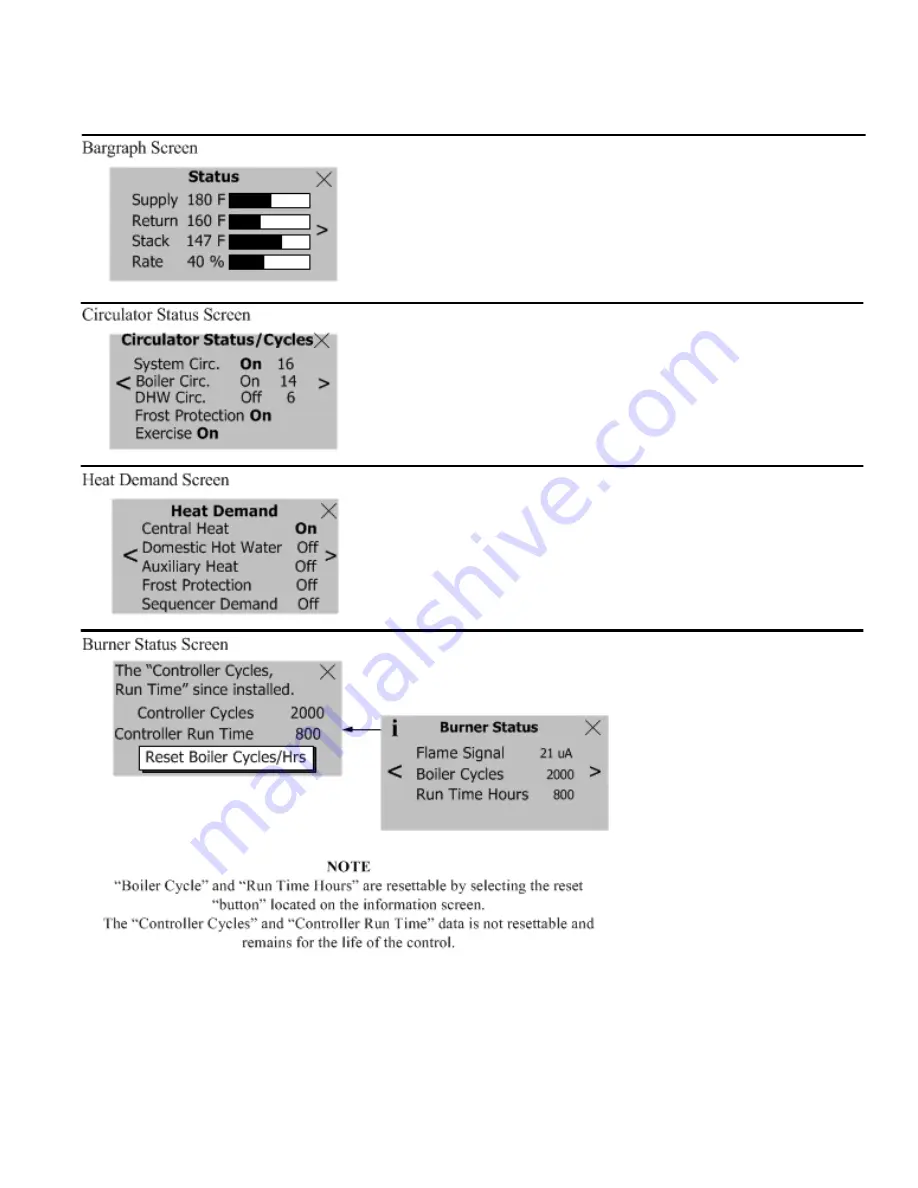

Bargraph Screen

The bargraph screen presents measured values for easy comparison. An

information screen provides monitoring of “Rate Demand To Fan” and “Fan

Speed Feedback”. These additional monitoring points are provided to help

monitor blower performance.

Pumping is a major part of any hydronic system. This screen provides the

status of the boiler’s demand to connected pumps as well as the status of Frost

Protection and pump Exercise functions.

This screen provides the status of the boilers five (5) possible heat demands.

When demand is off the Control has not detected the call-for-heat. This screen

allows the user to determine which demands are present when more than one

demand is present.

Cycles and Hours

Boiler cycles and hours are used

to monitor the boilers overall

compatibility to the heating load.

Excessive cycling compared to run

time may be an indication of pumping,

boiler sizing or adjustment issues.

i

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...