7

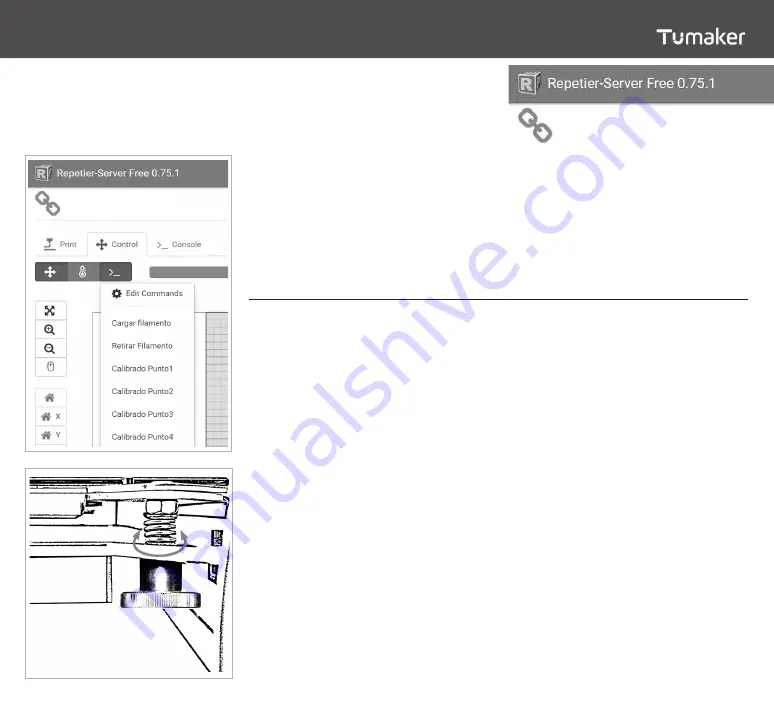

The calibration process is essential for

optimal printer operation and quality

prints. The distance between the

nozzle and the bed has to be perfectly

measured.

In order to obtain a correct calibration

we must follow the simple process

explained below.

Using a sheet of 80g/m² A4 paper,

the calibration wizard of the Repetier

Server software and the nuts under the

bed will make the operation easy.

1. Enter an Internet browser and type

the IP we have previously assigned in

the machine adding “:3344” at the end.

We will enter

Repetier Server

2. Click on the

control tab

3. Display the “

>_” menu

4. Select point by point

The first point will be one of the

corners of the bed. When the head is

positioned, place the sheet between

the bed and the nozzle. In order for the

calibration to be correct, the foil must

be moved between the two elements

opposing a little resistance. If there

is no resistance, is that we have too

much distance between the bed and

the head, therefore we must adjust the

distance by loosening the nut under

that corner until it is optimal. On the

other hand, if the distance is too small,

we must tighten the nut to increase it.

This process will be carried out in all of

the three points. There is a fourth point

in the middle of the bed to check if the

calibration has been made correctly.

The calibration with four points will

allow us to improve the flatness of the

surface of the bed, going from 0.2 mm

of the previous model to 0.1 mm.

This will allow larger parts to be printed

with a smaller layer height on the first

layer and avoid clogging due to nozzle

occlusions in high areas.

PRINTER CALIBRATION

Voladora

NX +

Voladora

NX +