TractionAir

22

‘Pressure Sensor Fail – Contact Service Agent’

will not display until the next

compare failure.

After an alarm, both PT1 and PT2 pressures will be displayed and updated every

second. This will enable the operator to determine which sensor best matches

a manual pressure gauge reading of the tyre pressure. a) above is then used to

select this sensor to control the tyre pressure until the faulty sensor is replaced

and PT1+PT2 selected.

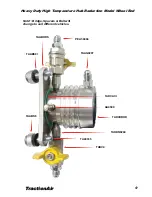

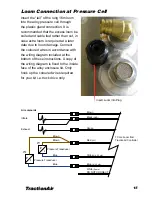

Pressure Transducer Test

1. Ensure the ECU is turned on

2. Go to the Pressure Cell and open the lid.

3. Using a DC Volt meter measure the Transducer supply voltage between

Terminal 4 (+ve) and Terminal 2. It should be between 8 and 10V. If not

check that the RED wire is tight in Terminal 4 and that all the pins are

correctly inserted in the 10 way ECU connector. Then check the wiring loom

for damage.

4. If the voltage is OK go to the next step.

5. Remove the yellow wire from terminal 5 and connect

a DC Amp meter in series with this wire and terminal 2.

6. If the reading is not between 4 and 20mA.

(milliamps), you will have to replace the

pressure transducer.

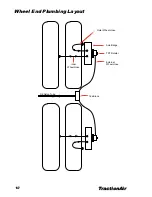

Park up

Taps On (handles in line)

Taps Off (handles at 90 °)

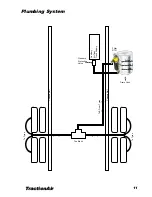

When parking up the vehicle overnight or any

other extended time period, it is very important

that

all wheel end axle bridge ball valves are

turned off.

TractionAir can mask small leaks and

punctures that may be present in a single tyre

that left overnight, could result in all tyres losing

pressure and breaking their beads. The ball valves

located on the two brass TA37004 tees are there

primarily to allow quick isolation of a wheel group

in the event of a blown hose etc.

Leave these taps on overnight.

Summary of Contents for TractionAir

Page 27: ...TractionAir 27...