30

EN

electric heater TEH 200 / TEH 300 / TEH 400

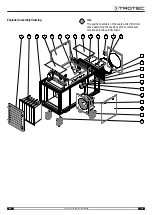

List of spare parts

Spare parts

TEH 200

TEH 300

TEH 400

Item

Designation

Quantity Trotec no.

Trotec no.

Trotec no.

1

Main switch

1

P 1000 1454

P 1000 1454

P 1000 1532

2

Heating elements

6 x P 1000 1905

12 x P 1000 1905

18 x P 1000 1905

3

LED element white 24 V

2

P 1000 1447

P 1000 1447

P 1000 1447

4

LED element green 24 V

1

P 1000 1445

P 1000 1445

P 1000 1445

5

LED element red 24 V

1

P 1000 1446

P 1000 1446

P 1000 1446

6

Indicator light yellow

1

P 1000 1450

P 1000 1450

P 1000 1450

7

Indicator light green

1

P 1000 0244

P 1000 0244

P 1000 0244

8

Indicator light red

1

P 1000 1448

P 1000 1448

P 1000 1448

9

Indicator light white

1

P 1000 1449

P 1000 1449

P 1000 1449

10

Air filter

1

P 1000 1563

P 1000 1563

1 x P 1000 1563

1 x P 1000 1564

11

Cam switch

1

P 1000 1455

P 1000 1455

P 1000 1455

12

Trestle roller

2

P 1000 1394

P 1000 1394

P 1000 1394

13

Lockable swivel castor

2

P 1000 1393

P 1000 1393

P 1000 1393

14

Push button green

1

P 1000 1443

P 1000 1443

P 1000 1443

15

Push button red

1

P 1000 1444

P 1000 1444

P 1000 1444

16

Control cabinet filter TEH

1

P 1000 1392

P 1000 1392

P 1000 1392

17

Radial fan

1

P 1000 1383

P 1000 1994

P 1000 1384

18

Relay

2

P 1000 6608

P 1000 6608

P 1000 6608

19

Operating hours counter

1

P 1000 1477

P 1000 1477

P 1000 1477

20

Lateral insulation

Base insulation

2 x P 1000 1989

2 x P 1000 1509

2 x P 1000 1989

2 x P 1000 1509

2 x P 1000 1512

2 x P 1000 1511

21

Pressure sensor

1

P 1000 1388

P 1000 1388

P 1000 1388

22

Semi-conductor relay

4 x P 1000 1431

8 x P 1000 1431

12 x P 1000 1431

23

Load relay 24 V

4 x P 1000 1238

8 x P 1000 1238

12 x P 1000 1238

24

Power adapter

1

P 1000 1313

P 1000 1313

P 1000 1313

25

Safety temperature limiter

1

P 1000 1432

P 1000 1432

P 1000 1432

26

Fuse C 10 A

1

P 1000 4058

P 1000 4058

P 1000 4058

27

Fuse C 16 A

1

P 1000 4057

P 1000 4057

P 1000 4057

28

Fuse B 32 A

2 x P 1000 4056

4 x P 1000 4056

6 x P 1000 4056

29

Temperature probe

1

P 1000 1430

P 1000 1430

P 1000 1430

30

Temperature probe

1

P 1000 1429

P 1000 1429

P 1000 1429

31

Isolating terminal

1

P 1000 1561

P 1000 1561

P 1000 1561

32

Protective frame (incl. mounting brackets)

1

P 1000 6972

P 1000 6972

P 1000 6973

33

Air filter inspection door

1

P 1000 6974

P 1000 6974

P 1000 6975

34

Fan cover

2

P 1000 6976

P 1000 6976

P 1000 6977

35

Control cabinet cover

1

P 1000 6978

P 1000 6978

P 1000 6979

36

E-heater cover

1

P 1000 6980

P 1000 6980

P 1000 6981

37

Spigot

1

P 1000 1386

P 1000 1386

P 1000 1387

38

Cover

2

P 1000 1982

P 1000 1982

P 1000 1983

Summary of Contents for TEH 200

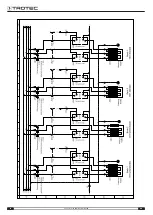

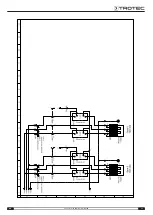

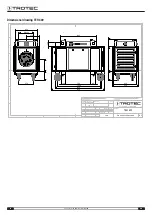

Page 16: ...16 EN electric heater TEH 200 TEH 300 TEH 400 Circuit diagram TEH 200 300 400 ...

Page 17: ...EN 17 electric heater TEH 200 TEH 300 TEH 400 ...

Page 18: ...18 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 19: ...EN 19 electric heater TEH 200 TEH 300 TEH 400 ...

Page 20: ...20 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 21: ...EN 21 electric heater TEH 200 TEH 300 TEH 400 ...

Page 22: ...22 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 23: ...EN 23 electric heater TEH 200 TEH 300 TEH 400 ...

Page 24: ...24 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 25: ...EN 25 electric heater TEH 200 TEH 300 TEH 400 ...

Page 26: ...26 EN electric heater TEH 200 TEH 300 TEH 400 ...