4

EN

electric heater TEH 200 / TEH 300 / TEH 400

Warning

In order to avoid overheating and fire hazards, the

heater must not be covered.

Behaviour in the event of an emergency

1. Immediately switch the device off via the main emergency

stop switch or the emergency stop at the upstream

distributor.

2. Remove persons from the danger area.

3. Disconnect the device from the electric circuit.

4. Do not reconnect a defective device to the mains.

Information about the device

Device description

The electric heater was designed as a robust, mobile unit also

to be positioned outdoors.

The device comes equipped with two lockable swivel castors (5)

and two trestle rollers (7) each. Forklift pockets and crane lugs

are attached to the housing as transport aids, enabling

convenient transport and space-saving storage by stacking up

to 3 devices on top of each other.

The housing is designed as welded frame construction and

provided with partially removable steel sheet panels. The

electrical control box made of steel is mounted in horizontal

position, protected between the stacking handle bars on the

housing, and contains all switching devices, operating

elements, indicator lights, safety devices and the control unit.

All steel and sheet metal parts are galvanized and powder-

coated.

The device is designed ready-to-install and comes with all the

electrical and mechanical components as well as safety

installations required for safe and functional operation.

To ensure safe transport and operation, the device is also

equipped with a shock protection frame.

Functioning principle

The air is taken in by the fan via the integrated bag filter (10)

and heated by means of the multi-stage electric heating. Four

different temperature levels can be selected between 0 and

100 %. These are kept constant by the integrated controller

with the maximum outlet temperature being reduced to approx.

60 °C (±5 °C).

Thanks to the two-stage fan operation a higher temperature

increase can be achieved by selecting the lower stage (approx.

2/3 of the nominal air volume). The integrated, electronically

controlled control unit with air volume flow measurement and

automatic rotational speed control of the fan ensures nearly

constant volumetric flow rates covering a wide load range (e.g.

for variable hose lengths).

The temperature increase refers to the sucked in air

temperature (usually the ambient temperature) and is increased

according to the preselection. The temperature sensors at air

inlet and outlet transmit the current temperature values to the

control unit, which then, depending on the demand, keeps the

preselected temperature increase constant by means of the

control and operation of individual heating elements or the

entire heater.

Summary of Contents for TEH 200

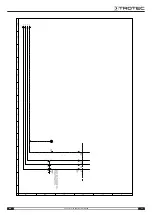

Page 16: ...16 EN electric heater TEH 200 TEH 300 TEH 400 Circuit diagram TEH 200 300 400 ...

Page 17: ...EN 17 electric heater TEH 200 TEH 300 TEH 400 ...

Page 18: ...18 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 19: ...EN 19 electric heater TEH 200 TEH 300 TEH 400 ...

Page 20: ...20 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 21: ...EN 21 electric heater TEH 200 TEH 300 TEH 400 ...

Page 22: ...22 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 23: ...EN 23 electric heater TEH 200 TEH 300 TEH 400 ...

Page 24: ...24 EN electric heater TEH 200 TEH 300 TEH 400 ...

Page 25: ...EN 25 electric heater TEH 200 TEH 300 TEH 400 ...

Page 26: ...26 EN electric heater TEH 200 TEH 300 TEH 400 ...