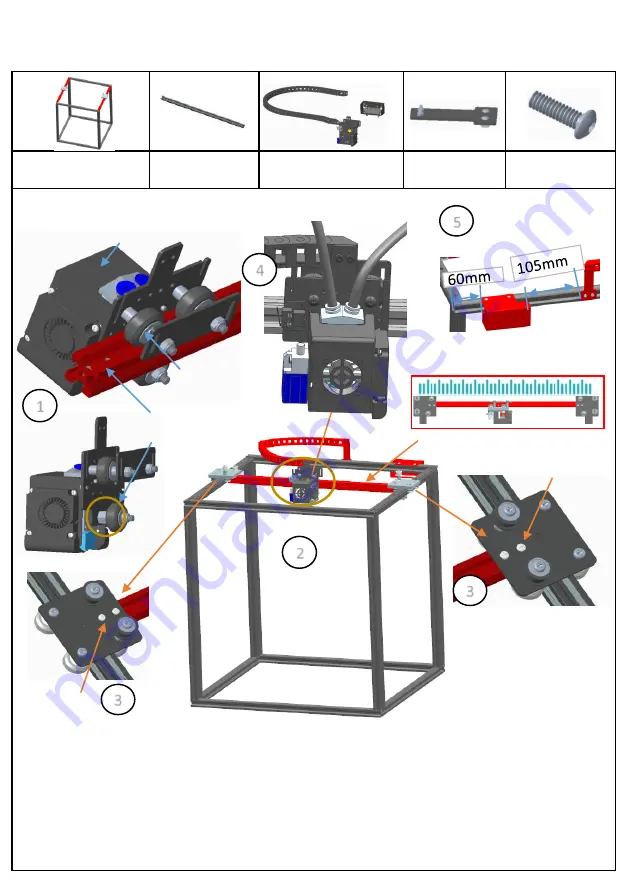

Assembly material specification and quantity

:

basic frame

1pcs

aluminum 4

20*20*554 1pcs

Print head parts

1pcs

drag chain

plate

1pcs

screws RM4*20

4pcs

1

As shown in Figure 1, the pulley on the print head penetrates into

the sliding slider of aluminum profile 4 smoothly without any gap

shaking

pulley

Aluminum profile hole

Eccentric nut

print head

2-M4*12

2-M4*12

3

3

2

4

5

1.Insert the print head into the aluminum profile 4, pay attention to the M4 screw hole direction,

as shown in Figure 1

2.Install the x-axis aluminum profile assembly into the underframe to align the hole position,

screw on the screw RM4 * 12 and do not lock it temporarily, as shown in Figure 2

3.Move the left and right sliders, after confirming that the x-axis aluminum profile component

moves flexibly, lock the RM4 * 12 screw

4.After adjustment, lock the RM5 * 25 screw on the y-axis guide rail, and move the x-axis

aluminum profile assembly again. Please adjust repeatedly to ensure that the slide plate moves

flexibly without any space shaking after locking the screw.

6

The skateboard is in line with

the X-axis guide

Pay attention to the

smooth adjustment:

please turn the

eccentric nut on the left

/ right sliding plate to

make the sliding plate

smooth without gap

Step 3

:

Print head assembly

Summary of Contents for X5SA-400-2E

Page 1: ...X5SA 2E Installation Manual ...

Page 21: ...17 5 Interface operation and printing ...

Page 26: ...2 How to use slice software Type setting follow the steps below to complete the setting 22 ...

Page 31: ......

Page 32: ......