LASER ENGRAVING&CUTTING CONTROLLER AWC608

、

87

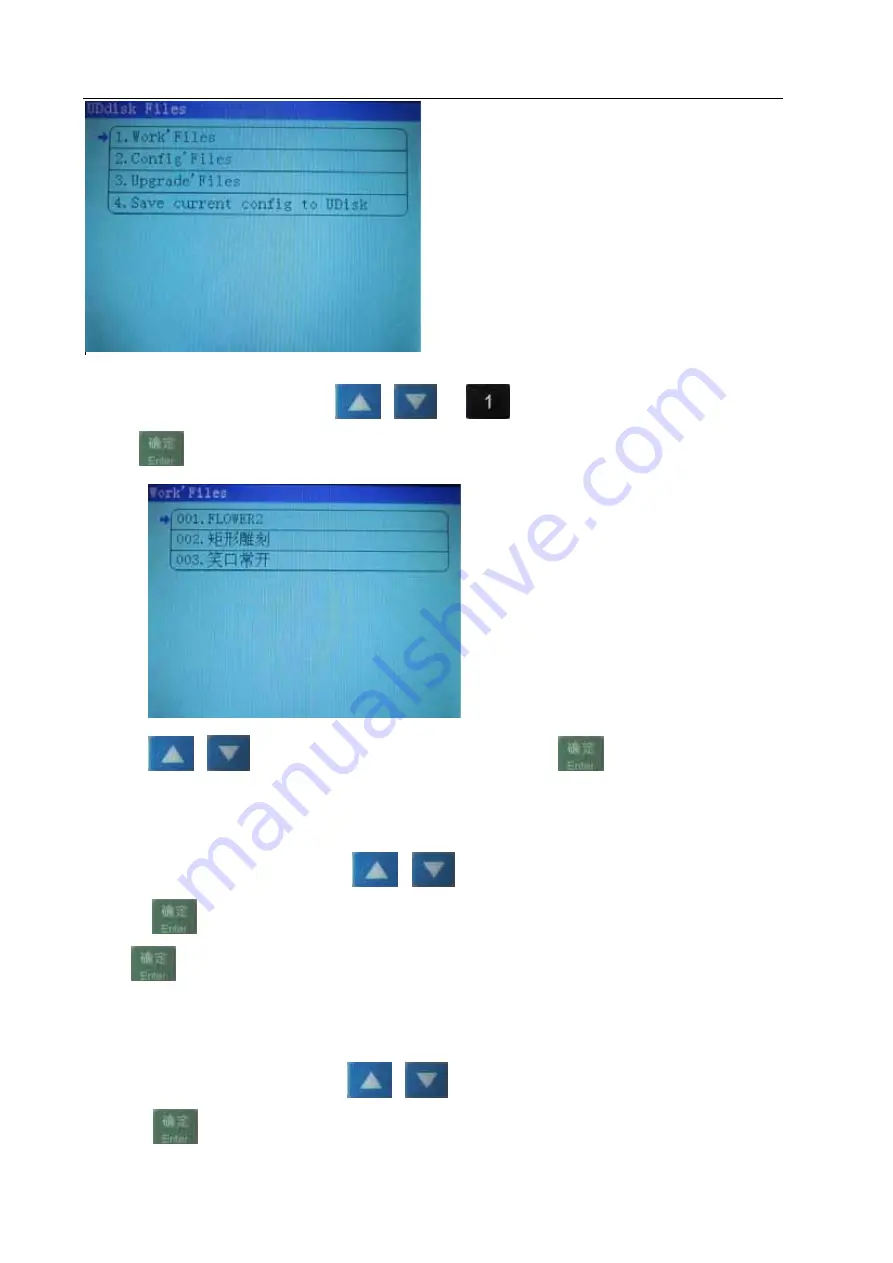

View 8-4-1

8.4.1.1 Work file (refer to view 8-4-1)

Under the

【

UDisk file

】

, press

or

or

to move cursor onto item

【

work’ files

】

,

press

to enter into

【

work’ files

】

interface:

view8-4-1-1

Press

or

to move cursor onto one file, and then press

, system will copy the file into

the memory of control panel. Then this file can be output. (suffix of work file is ud5)

8.4.1.2 Config File (refer to View8-4-1)

Under

【

UDisk file

】

interface, press

or

to move cursor onto item

【

Config’ files

】

,after

pressing

to enter into

【

Config ’ files

】

interface, move cursor to select one parameter file, and then

press

, system will update the parameter of control panel according to parameter file.(suffix of

parameter file is cf5).

8.4.1.3 System upgrade file

(refer to graphic 8-4-1)

Under

【

UDisk file

】

interface, press

or

to move cursor onto item

【

Upgrade’ files

】

.After

pressing

to enter into

【

Upgrade’ files

】

,move cursor to select one upgrade file, and then