A

Q U A S E N S A T I O N

A S 2 0 0 0 T / A S 2 0 0 0

7

Fig.6

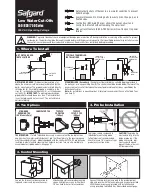

REMOVING THE COVER

To remove the cover, first pull off the temperature

control only

(fig.6)

–

not the flow control.

This will reveal the maximum temperature stop

(fig.7)

. This should be left in position.

NOTE: If adjustment of the maximum temperature

stop is required, refer to section

’Adjusting the

maximum temperature stop’

.

Remove the two cover fixing screws – top and

bottom

(fig.8)

.

Carefully lift the cover away from the backplate.

Lay aside the cover and screws until the unit is

fully installed.

NOTE: When removing the cover for future

maintenance purposes etc., be aware of the lead

connected to the PCB unit. Carefully pull off the

lead from the PCB. Do not let the cover dangle by

the lead.

PLUMBING CONNECTIONS

Plumbing to precede wiring

NOTE: The outlet of the shower must not be

connected to anything other than the hose and

sprayhead supplied.

DO NOT use jointing compounds on any pipe

fittings for the installation.

When connecting pipework avoid using tight 90°

elbows. Swept or formed bends will ensure

optimum performance.

Isolate the mains water supply to the cold water

cistern. Drain the hot and cold pipes by opening

all taps.

The hot water supply can be taken from the hot

supply pipe from the cylinder, ensuring that it is

the first draw-off below the ventilation pipe tee in

order to minimise the effects of water draw-off

elsewhere in the house

(see fig.2)

.

NOTE: There must not be any other draw-offs

between the take-off point and the shower.

A dedicated cold water supply must be taken

directly from the cold water cistern to the shower.

This draw-off must be positioned 25mm below

the cold feed connection to the hot water cylinder

on the opposite side of the cistern to the float

operated valve

(see fig.2)

. This minimises air

ingress into the pipework.

Maximum

temperature

stop

Fig.7

Fig.8

Summary of Contents for Aquasensation AS2000

Page 28: ...UKAS QUALITY MANAGEMENT 003 ...