Model 601SBM Low Profile Clamshell

92-0092 Rev. 210701

25

Tool Bit Set-Up

Select the proper Tool Bit set. Refer to the section “Tool Bits.”

WARNING

WARNING: Use of dull or improperly designed Tool Bits or Tool Bits not

manufactured by Tri Tool Inc. may result in poor performance and may constitute

abuse of this machine and therefore voids the Tri Tool Inc. factory warranty.

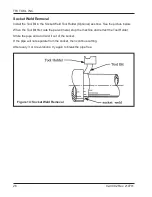

Install the Tool Bits into the Tool Blocks. Refer to the section ‘Tool Bits’ for installation

drawings.

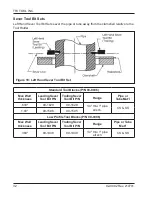

Approximately .50" (13 mm) should be protruding from the end of the Tool Holders.

Tighten the Tool Bit Set Screws, then verify that there is adequate clearance between the Tool

Bits and the pipe by rotating the Headstock by hand.

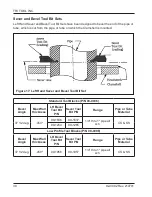

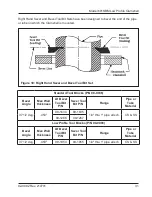

The Leading Tool Bit should contact the pipe approximately .020" to .040" (.51 mm to 1.0 mm)

before the Trailing Tool Bit.

Go to “General machine sequence.

Severing and Single Beveling or Severing and Double Beveling

Simultaneously

When the Tool Bits are within about .040" (1.0 mm) of severing the pipe, disengage the Feed

Pin and let the Headstock rotate 2 to 3 times to clear the chip.

Retract the Tool Holder which holds the Bevel Tool Bit, be sure that the Feed Sprocket is

aligned properly.

Complete the sever.

After the sever is complete, reposition the Bevel Tool Bit so that it continues cutting until the

desired land thickness is obtained.

Go to “Monitoring the cutting operation.”

Figure 13: Tool Bit Adjustment

Summary of Contents for 601SBM

Page 1: ...Operation Manual 92 0092 Rev 210701 Model 601SBM Low Profile Clamshell ...

Page 44: ...TRI TOOL INC 92 0092 Rev 210701 42 HOUSING ASSY DRIVE P N 19 0285 5 1 2 4 7 9 8 6 3 ...

Page 46: ...TRI TOOL INC 92 0092 Rev 210701 44 MOTOR ASSY AIR P N 57 0083 5 4 2 3 8 1 6 7 ...

Page 54: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 55: ......