TRI TOOL INC.

92-0092 Rev. 210701

24

Configure the Clamshell for the Specific Task Required

Select the proper Tool Blocks

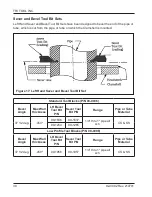

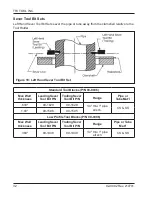

Tool Block Selection

Tool Block

Assy

Height from Centerline of the

cut to the Headstock Face

Tool Block Travel

08-0036

1.50"

38.1 mm

.63"

16.0 mm

08-0096

.51"

13.0 mm

.50"

12.7 mm

Mount the Tool Blocks and Tripper Block to the Clamshell.

Check the adjustment of the slides and mesh of the Tripper Pin with the Feed Sprocket.

Select the proper Clamping Pad Set. Refer to the table ‘Pad Set Selection’.

Install the Clamping Pad Set into the clamshell.

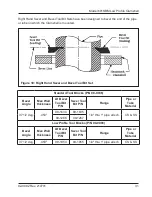

If using the Fixed Clamping Pad Set then install the Clamping Pad Set so that the pipe is on

the fixed Pads or vice versa.

Fixed Pads should be located 90

o

from each other.

Pad Set Selection

Pipe Size

OD

P/N of Pad Sets

1.00"

1.315"

33.4 mm

67-3156

1.250"

31.8 mm

67-3157

1.125"

28.6 mm

67-3158

.75"

1.050"

26.7 mm

67-3159

1.000"

25.4 mm

67-3160

.875"

22.2 mm

67-3161

.50"

.840"

21.3 mm

67-3162

.750"

19.1 mm

67-3163

.38"

.675"

17.1 mm

67-3164

.625"

15.9 mm

67-3165

.25"

.540"

13.7 mm

67-3166

Summary of Contents for 601SBM

Page 1: ...Operation Manual 92 0092 Rev 210701 Model 601SBM Low Profile Clamshell ...

Page 44: ...TRI TOOL INC 92 0092 Rev 210701 42 HOUSING ASSY DRIVE P N 19 0285 5 1 2 4 7 9 8 6 3 ...

Page 46: ...TRI TOOL INC 92 0092 Rev 210701 44 MOTOR ASSY AIR P N 57 0083 5 4 2 3 8 1 6 7 ...

Page 54: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 55: ......