Model 601SBM Low Profile Clamshell

92-0092 Rev. 210701

23

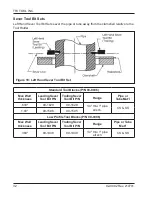

Check for proper alignment of the Feed Sprockets. Refer to the picture “Approach of the Feed

Pin to the Feed Sprocket.”

Run the Headstock slowly with the Feed Pin ‘in’ to insure that the Sprocket is set right. (Do not

run at full speed during the first revolution.)

NOTE:

The Feed Pin will break if the alignment of the Feed Pin to the Sprocket is not correct.

The Air Motor working speed will be about one half of the no-load speed. Refer to the chapter

on “Cutting Speeds” for speed selection charts.

Engage the feed by pushing the Tripper Shaft in.

Monitor the cutting operation.

Apply cutting fluid as necessary.

If Chips build up so much that they tangle in the Clamshell, disengage the feed for 2-3

revolutions to clear the chip.

Then stop the Clamshell and remove the chips.

When the machine operation is finished, turn off the Air Motor by closing the Throttle Control

Valve.

CAUTION

CAUTION: In Line pipe stores energy.

When the pipe is severed, the pipe may move.

To prevent accidents due to the spring in the pipe system, be sure to secure the pipe on both

sides of the sever line in order to prevent differential movement of the pipe ends.

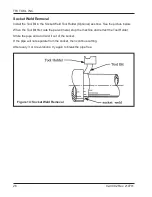

Retract the Tool Holders so that the Tool Bit(s) clear the pipe OD.

NOTE:

The Tool Holders are retracted by rotating the Feed Sprocket clockwise using the

special Spanner Wrench supplied with the Clamshell.

Run the Air Motor until the split-lines of the Headstock and the Housing match.

Loosen the Clamping Pads.

Remove the Clamshell from the pipe.

If the Clamshell must be split to remove it, be sure that both halves are properly supported.

Summary of Contents for 601SBM

Page 1: ...Operation Manual 92 0092 Rev 210701 Model 601SBM Low Profile Clamshell ...

Page 44: ...TRI TOOL INC 92 0092 Rev 210701 42 HOUSING ASSY DRIVE P N 19 0285 5 1 2 4 7 9 8 6 3 ...

Page 46: ...TRI TOOL INC 92 0092 Rev 210701 44 MOTOR ASSY AIR P N 57 0083 5 4 2 3 8 1 6 7 ...

Page 54: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 55: ......