Starter Work

40

CVRF-SVN005C-EN

•

To simplify future chiller trouble analysis, Trane

recommends removing all existing, non-essential

components from the starter panel enclosure.

Control Power Transformer

If the existing starter does not have 115 Vac 3 kVA of additional

control power, install a transformer (fieldsupplied) that will

provide 115 Vac to the Symbio™ control panel. (As just

described, transformer requirements are: line voltage primary/

115 Vac secondary, minimum capacity 3 kVA.)

Current Transformers, CTs

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with a CAT III or IV voltmeter rated per

NFPA 70E that all capacitors have discharged.

WARNING

PPE for Arc/Flash Required!

Failure to wear appropriate PPE could result in death or

serious injury. On this unit, if the handle shield is

cracked the circuit breaker could arc/flash when reset.

To avoid being injured, technicians MUST put on all

necessary Personal Protective Equipment (PPE), in

accordance with NFPA70E for arc/flash protection,

PRIOR to entering the starter panel cabinet.

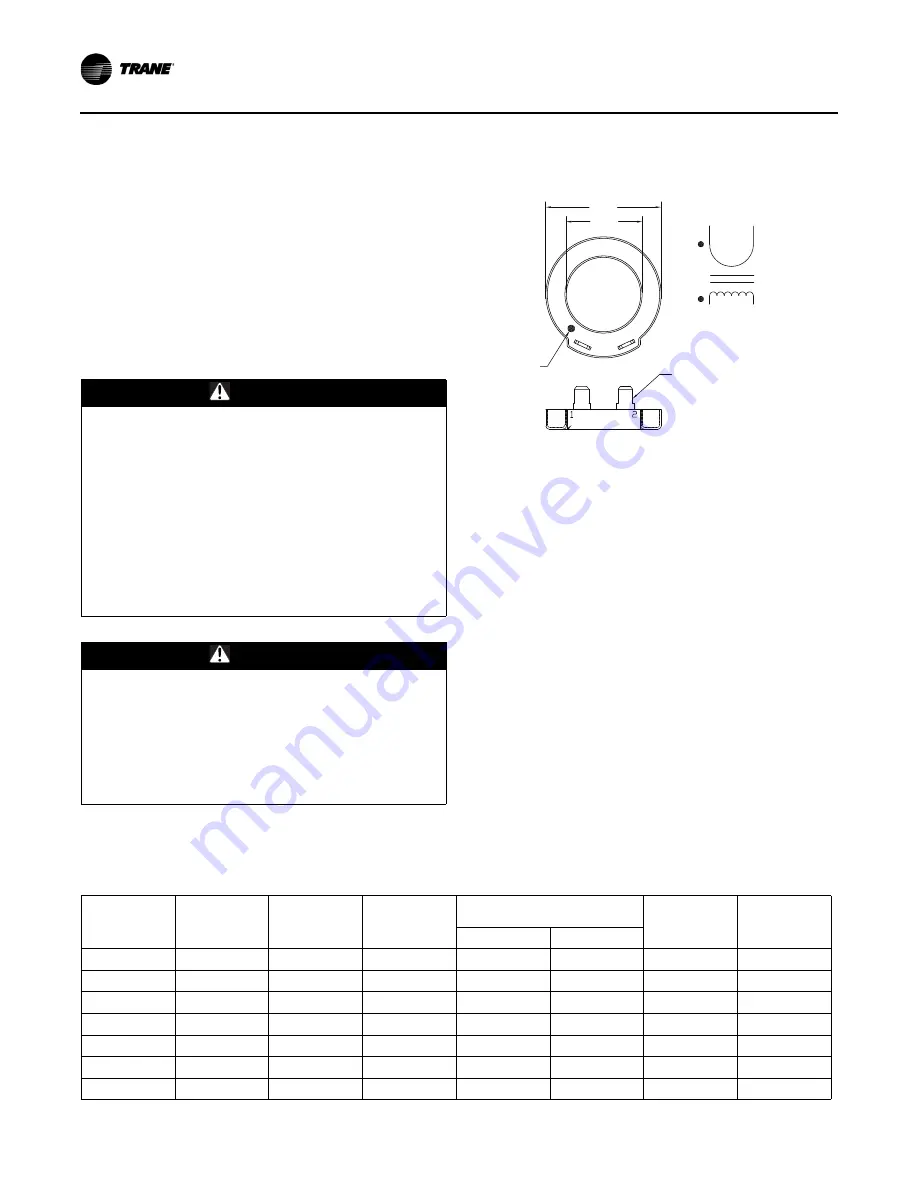

Three new current transformers CTs (“donut” shape) are

optional to re-work the starter. If used, install these three new

CTs as shown on wiring diagram. Pay careful attention to the

polarity dot and its orientation. The polarity dot should face

incoming power, in other words, towards the disconnect.

Figure 55. Current transformer, single turn-down

Wire the leads from the CT male quick connects to the starter

module as shown on the wiring diagram. Use female insulated

quick connect terminals.

The application of Symbio™ chiller controls to a medium

voltage chiller recommends specific use of the dual current

transformer (CT) application, rather than a single CT which is

a common option on low voltage applications (600 Vac or less).

Refer to CVRD-SVN11*-EN for wiring of medium voltage CT

applications.

The dual CT installation uses a primary CT that reduces the

amperage to less than 5 amps. A second CT is then used to

reduce the current input to the starter module to a nominal 100

mA value. Use dual CT data tables in the startup and

programming manual CVRE-SVP01A-EN, or the latest

version.

It is recommended that you confirm the correct CT has been

provided before starting installation. Before wiring the starter

module and CT be sure to confirm incoming power phasing. If

Phase A, B, and C are wired in the wrong order the controls will

not allow the motor to start. Use the phase meter on the low

voltage side of the potential transformer. Do NOT use the

meter on the primary side where there is medium voltage

because it probably exceeds the safe operating voltage range

of most service meters.

1/4 in. male quick connect

2 places

Polarity Dot

DIM “B”

DIM “A”

Schematic

Table 9.

CT specifications for single transformer per phase

Actual Motor

RLA (A)

CT Part Number

CT Ratio (A:A)

CT Rating (A)

Diameter

(a)

(inches)

Primary

Turns

CT Meter

Scale

Inside A

Inside B

67-100

TRR02028

40:00.1

100

2

3.35

1

100

100-150

TRR00715

30:00.1

150

2

3.35

1

150

134-200

TRR02029

20:00.1

200

2

3.35

1

200

184-275

TRR02030

35:00.1

275

2

3.35

1

275

267-400

TRR02031

40:00.1

400

2.5

3.95

1

400

334-500

TRR01142

20:00.1

500

2.5

3.95

1

500

467-700

TRR01255

40:00.1

700

2.5

3.95

1

700