Installation

CVRF-SVN005C-EN

17

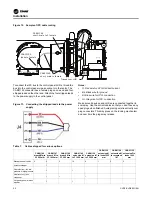

Oil Pressure Transducer Installation

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with a CAT III or IV voltmeter rated per

NFPA 70E that all capacitors have discharged.

WARNING

PPE for Arc/Flash Required!

Failure to wear appropriate PPE could result in death or

serious injury.

On this unit, if the handle shield is cracked the circuit

breaker could arc/flash when reset. To avoid being

injured, technicians MUST put on all necessary

Personal Protective Equipment (PPE), in accordance

with NFPA70E for arc/flash protection, PRIOR to

entering the starter panel cabinet.

The two existing oil pressure transducers will be replaced with

new transducers.

1. Use Loctite 565 on pressure transducer so connection can

be broken without heat if future replacement of pressure

transducer is required. Note which line is oil pump

discharge pressure and which is sump pressure. Quickly

attach sensors to lines to avoid large quantities of air

entering machine.

Adapter fittings are provided with the kit. The transducers

can be mounted in any direction. Lines should be routed

and transducers mounted to minimize any potential

stacking of liquid on top of the transducers.

2. Label pressure transducers using labels provided.

Sensor Installation and Wiring

Existing UCP2 sensors cannot be used with a Symbio™

retrofit. It is recommended that existing bulb wells be used.

Installing new wells would necessitate opening the chiller to

atmosphere

WARNING

Refrigerant under High Pressure!

Failure to follow instructions below could result in an

explosion which could result in death or serious injury

or equipment damage.

System contains refrigerant under high pressure.

Recover refrigerant to relieve pressure before opening

the system. See unit nameplate for refrigerant type. Do

not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives.

If installing new bulb wells (optional), use safe refrigerant

practices to evacuate the chiller. Install and wire each of the

temperature sensors listed below.

When the sensor is installed in a bulb well, be sure to:

•

Add thermastic paste to each bulb well before inserting the

sensor.

•

Ensure that the sensor “bottoms out” at the base of the bulb

well.

It is recommended that sensors “1” through “3” be mounted in

wells. The rest may be installed externally. Connect all

Symbio™ temperature sensors to the main IPC bus using the

provided pluggable cables.

NOTICE

Equipment Damage!

Failure to follow instruction below could result in

equipment damage. Never route low-voltage leads with

other conductors carrying 30 or more volts.

The Symbio™ component identification is in parenthesis

following each sensor name:

1. Oil tank temperature sensor (4R5)

2. Evaporator leaving water temperature sensor (4R7)

3. Evaporator saturated refrigerant temperature sensor

(4R10)

4. Condenser entering and leaving water temperature

sensors (4R8 and 4R9)

5. Evaporator entering water temperature sensor (4R6)

6. Condenser saturated refrigerant temperature sensor

(4R11)

Locate sensor at the bottom of the condenser or on the

condenser liquid line upstream of any orifices or float

valves.

Note:

If unit has an EarthWise™ purge, PRGD (CH530

controls), the sensor bound as Condenser Saturated

Refrigerant Temperature Sensor (used as Purge

Liquid Temperature) cannot be used and will need to

be unbound. Install the temperature sensor sent with

the Tracer® AdaptiView™ components as described

above.