17

90

90

C) BLOCSTOP

®

BSO 2050

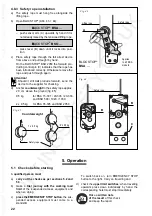

(Installation dimensions on page 18)

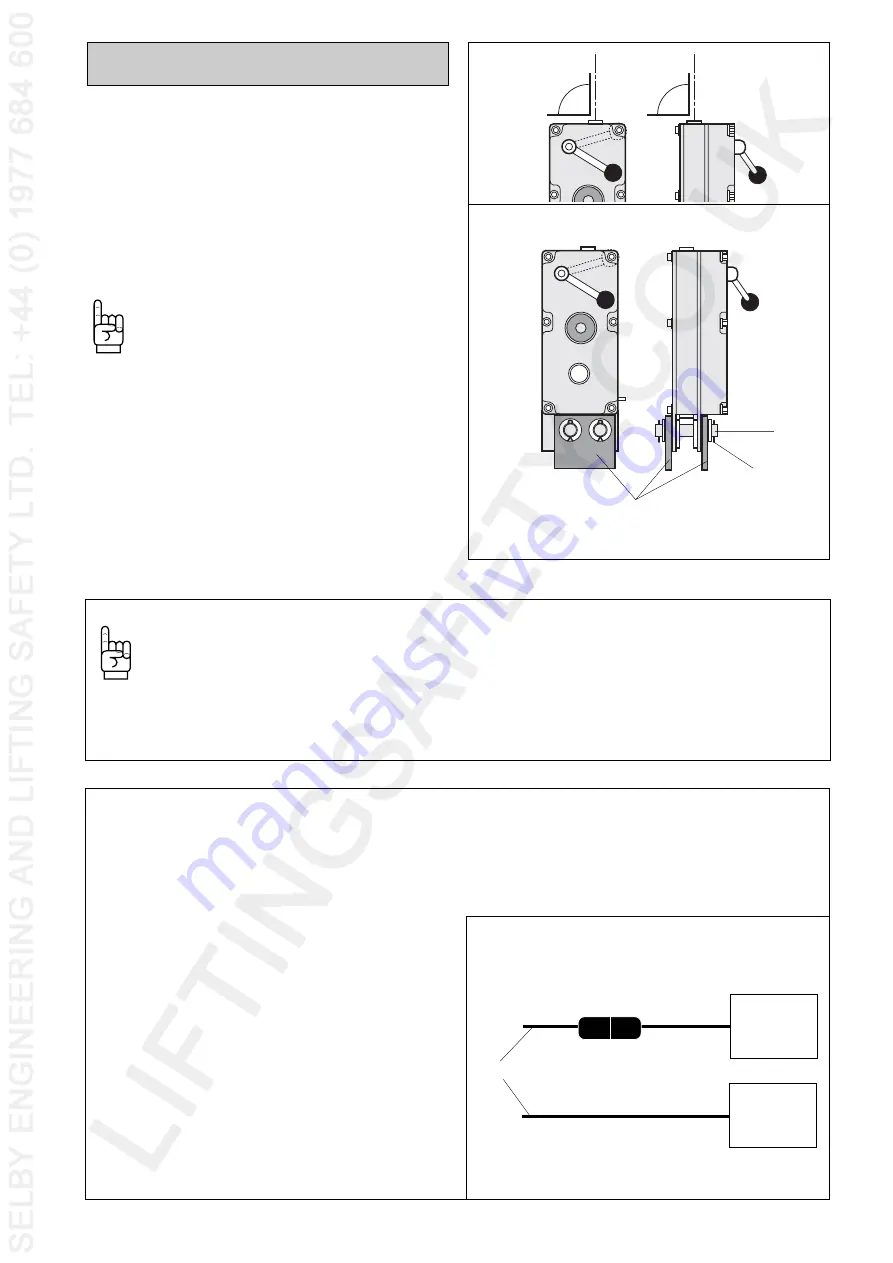

a)

The interval between safety and lifting rope is

not laid down; however it should be kept as

small as possible.

b)

The anchoring component must be provided for

at an appropriate interval to the hoist on the

suspended access equipment and indeed in such

a manner that the safety rope runs vertically

into the opening of the BLOCSTOP

®

(fig. 27).

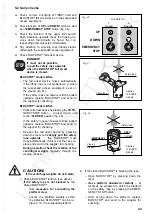

Attention!

The anchoring component (a) must consist of

two brackets so that the BLOCSTOP

®

is linked

to this on both sides (fig.28).

c)

Connect both anchor points of the BLOCSTOP

®

to the anchor component (a) of the working plat-

form with bolts (b).

Bolt diameter: 22 mm

Minimum quality:

Grade 8.8 (800 N/mm

2

800 MPa)

d)

The bolts must be secured against loss by fore-

locks (c) or equal value securing elements.

Fig. 27

Fig. 28

a

b

c

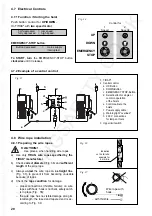

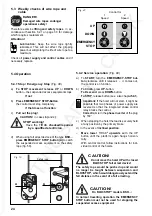

Applies only for BSO models with built-in limit switch:

4.4.4 Connection to the

TIRAK

®

control system

4.4.4.1 Function

If the BLOCSTOP

®

fall arrest device is closed, the

control current for the downward travel of the as-

signed hoist will be interrupted.

4.4.4.2 Connection ( fig. 29)

A) Plug connection

Connect limit switch cable (a) to the control box of

the assigned hoist with plug connection.

B) Fixed wired connection

Have limit switch cable (a) connected in the con-

trol box of the assigned hoist by a qualified

electrician in accordance with the wiring diagram

provided.

Fig. 29

a

Hoist

control

Plug connection

Hoist

control

Fixed wired connection

To be carried out

by electrician!

(Principle sketch)

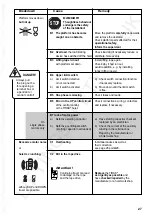

Attention!

Protect BLOCSTOP

®

devices against dirt!

Take appropriate action for ensuring that

no debris is carried into the BLOCSTOP

©

by

the rope.

This applies in particular during work with air-

placed concrete or with synthetic resin coatings

or similar!

Deposits of this nature can lead to malfunction

which endanger work safety!

BLOCSTOP

®

BSO 2050