15 |

11.1 General

Even though the CureView is designed to the highest specifications possible

the CureView has limitations. We simply are not able to go beyond the laws

of physics. In order to explain some of the limitations of the TQC CureView

the following chapter will include some of the intricacies of thermal

dynamics involved with using the CureView.

11.2 Basics of Gradient Ovens:

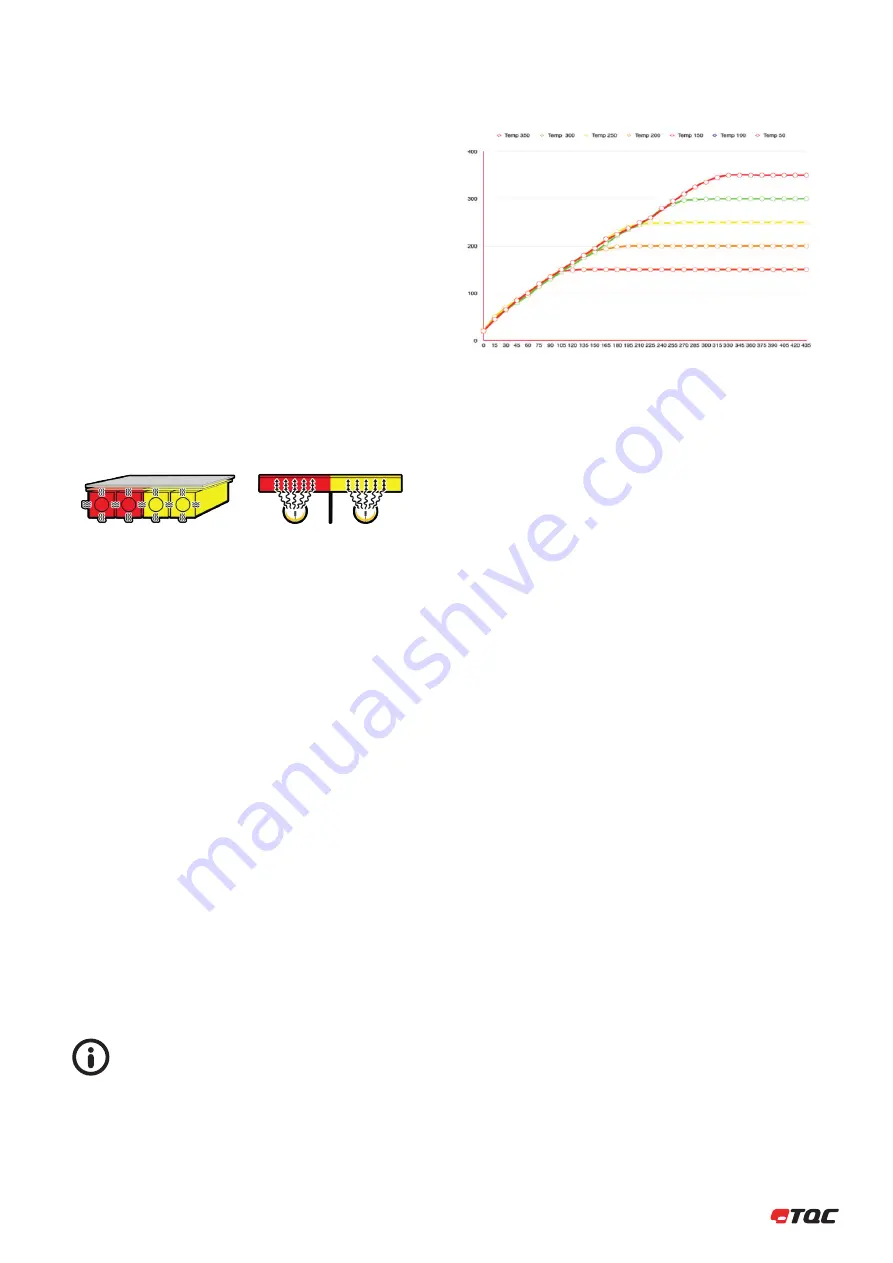

The TQC CureView is a new generation of Gradient-ovens that allows for

significantly more advanced tests and doesn’t require preheating. The

implementation of the latest heating techniques in the TQC CureView

provide a different heat transfer compared to that of older systems with

conventional heating. The direct IR-irradiation by the TQC CureView allows

for a significantly more efficient heating than traditional gradient oven

systems. Due to this new heating system multiple components and

procedures had to be changed in the machine. Below is a simplified image

highlighting the difference in build of conventional systems and the new

TQC CureView.

Due to the difference in construction the heat transfer is significantly

different. Where the older systems work based on conduction of heat the

TQC CureView is based on transmittance of energy by IR-radiation. Older

Gradient ovens often suffer from loss in efficiency by improper contact

between the heating element, glass-bed and/or test panel. Because older

models have the thermocouple installed directly at the heater, they have

been compensated for the offset that occurs due to the different contacts

required to transfer the heat. Any small misalignment or other problem will

result in a loss of efficiency. This will cause significant differences in the

temperature of the test-panel. The TQC CureView is created such that it

regulates the heaters based on the temperature probe that is positioned on

top of the panel, thus at the actual spot where the temperature is relevant.

When comparing old and new systems side by side there might be a

temperature offset that has to be accounted for. This off-set is due to

deviation from older machines. Where test were set to be performed at

180˚C / 356˚F they could actually have been performed at 150˚C / 302˚F.

This off-set varies depending on the condition of the old machines.

To determine this off-set it is recommended to measure the actual

temperature obtained on the surface of the test panel.

Due to the new and improved heating systems no preheating is required.

This eliminates an irregular heating of the panel and allows for a repeatable

ramping of the temperature on the panel. The ramping is controlled and will

follow the same slope for all temperatures. The ramping for the heating can

be programmed in the Gradient oven. Below graph shows a default slope

being equal for all set point temperatures.

All following examples of ramping and heating graphs are

generalized and not correlated to a specific substrate or

ramp speed unless otherwise stated.

In the following graph the vertical axis shows the temperature in ˚C and the

horizontal axis displays the time (s). All set temperatures follow the same

ramp. Adjusting the ramp value can control the ramp slope.

11.3 Substrate material

The main influence for differences between tests is the substrate that tests

are performed on. Different substrates react differently to heat. Some

substrate function as an isolator and others as an excellent conductor of

heat. This ability or it’s lack to conduct heat determine the maximal

temperature difference between 2 heaters. On a well conducting material

the difference between 2 elements is lower than on a less conducting

substrate. The property of metals to conduct heat is a temperature

dependent function. If a gradient from 25˚C to 125˚C / 77˚F to 257˚F

is obtainable this doesn’t mean that 125°C to 225°C / 257˚F to 437˚F is

possible as well or vice versa. In order to test for the suitability of a program

and/or substrate it is advised to run a test-run on uncoated substrate prior

to performing the real test.

Full thermal properties of a substrate can be calculated. Full calculations

and factors can be found in the “ Handbook of Chemistry and physics.”

Calculating the thermal response of panels is however tricky due to the

large number of variables.

11.4 Surrounding / environmental conditions.

The TQC CureView has been designed such that it will keep draft away

from the panel but still allow the panel to be visible. Though the Cureview

is designed to eliminate as many influences as possible. Small fluctuations

in the heating behavior can be caused by changes in temperature and

humidity of the surrounding air. These parameters not only influence

the heating capabilities of the CureView but in more significant manner

the evaporation of samples as tested according the ISO 2812-5 or curing

of powder coatings. Stable laboratory conditions are required to create

reproducible results. Please consult internal guidelines or international

standards for the required climatic conditions required for the performed

test.

11.5 Ramping

The TQC CureView can be set for custom ramping speeds. A Ramping

indicates the speed in degree per second the CureView will heat a panel.

The selected ramping will influence the amount of heat generated by the

lamps. The generated heat needs to flow from the bottom of the panel to

the top prior to being detected by the probes. This process depends on

the thermal properties of the test panel. Thickness, material type, surface

finishing and set end temperature all influence the thermal response. If the

ramping is set to high there might be an overshoot of the set temperature.

11 THERMAL DYNAMICS

Conventional heating

IR-heating

Summary of Contents for CureView AB8000

Page 2: ......

Page 28: ......

Page 30: ...30 Date Name Signature Signature Instructed by Operator list...