FU-92 FUEL SYSTEM - Injection Pump

(b) Check the adjusting lever movement.

Adjusting lever angle: 38-48°

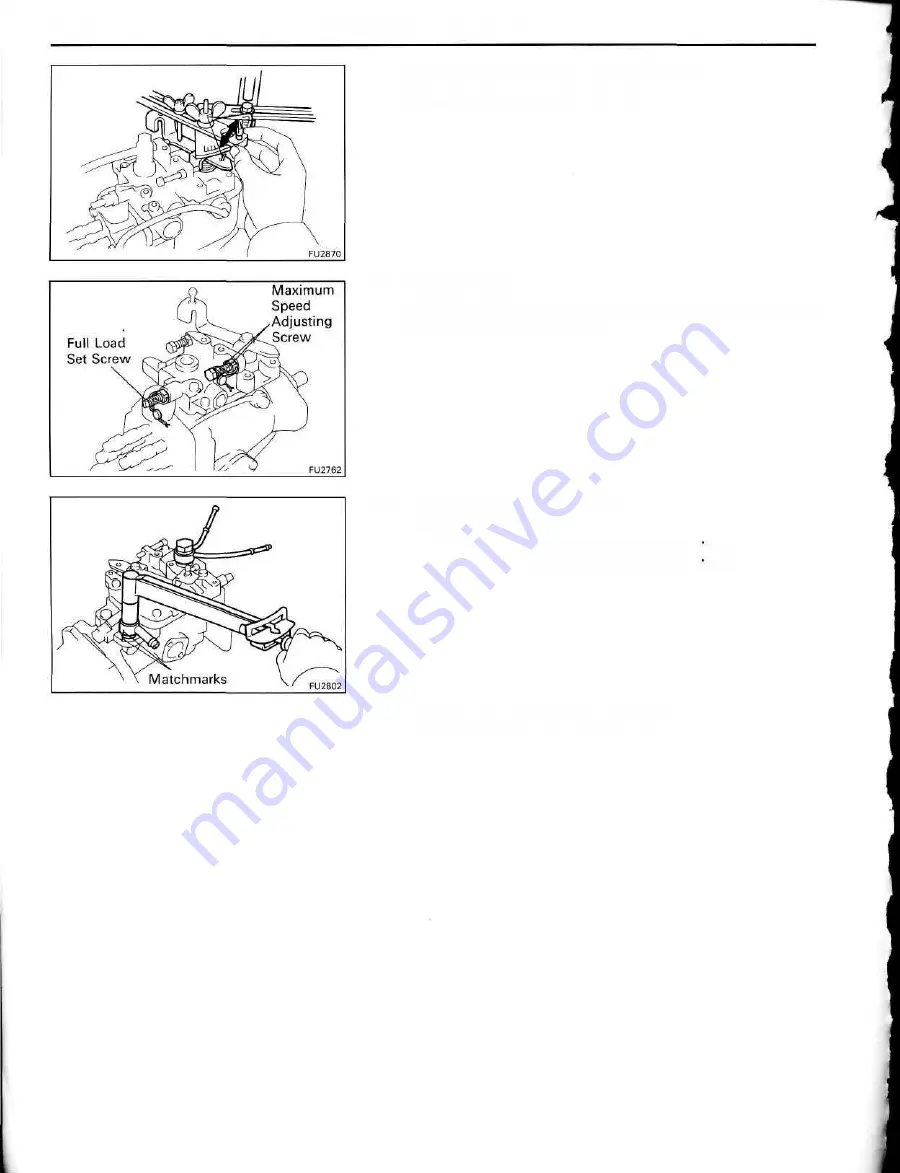

22. SEAL PARTS

Seal the maximum speed adjusting screw and full load set

screws with new lead seals.

23. INSTALL TWO FUEL PIPES

Torque:

Inlet 250 kg-cm (18 ft-lb, 25 N m )

Outlet 225 kg-cm (16 ft-lb, 22 N m )

24. INSTALL INJECTION PUMP STAY

Summary of Contents for 1HD-T

Page 1: ......

Page 53: ...EM 42 ENGINE MECHANICAL Timing Gears TIMING GEARS COMPONENTS ...

Page 65: ...EM 54 ENGINE MECHANICAL Cylinder Head CYLINDER HEAD COMPONENTS ...

Page 95: ...EM 84 ENGINE MECHANICAL Cylinder Block CYLINDER BLOCK COMPONENTS ...

Page 133: ...TURBOCHARGER SYSTEM Turbocharger TC 9 COMPONENTS ...

Page 145: ...FU 6 FUEL SYSTEM Fuel Heater System FUEL HEATER SYSTEM SYSTEM CIRCUIT ...

Page 166: ...FUEL SYSTEM Injection Pump FU 27 INJECTION PUMP REMOVAL OF INJECTION PUMP ...

Page 169: ...FU 30 FUEL SYSTEM Injection Pump COMPONENTS ...

Page 170: ...FUEL SYSTEM Injection Pump FU 31 COMPONENTS Cont d ...

Page 171: ...FU 32 FUEL SYSTEM Injection Pump COMPONENTS Cont d ...

Page 251: ...LU 4 LUBRICATION SYSTEM Troubleshooting TROUBLESHOOTING ...

Page 255: ...LU 8 LUBRICATION SYSTEM Oil Pump OIL PUMP COMPONENT ...

Page 272: ...ST 4 STARTING SYSTEM Pre Heating System Super Glow Type TIMER CHARACTERISTIC DIAGRAM Cont d ...

Page 282: ...ST 14 STARTING SYSTEM Starting System Circuit STARTING SYSTEM CIRCUIT Cont d ...

Page 340: ...B 1 STANDARD BOLT TORQUE SPECIFICATIONS Page STANDARD BOLT TORQUE SPECIFICATIONS B 2 ...

Page 343: ...C 1 SSTAND SSM Page SST SPECIAL SERVICE TOOLS C 2 SSM SPECIAL SERVICE MATERIALS C 6 ...